High-efficiency jaw plate with rear-mounted base

A rear-mounted, high-efficiency technology, applied in the direction of grain processing, etc., can solve the problems of insufficient strength of the base, affecting the matching accuracy, unreasonable layout design of "frame" and "space", and achieve the goal of increasing rigidity and enhancing crushing function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

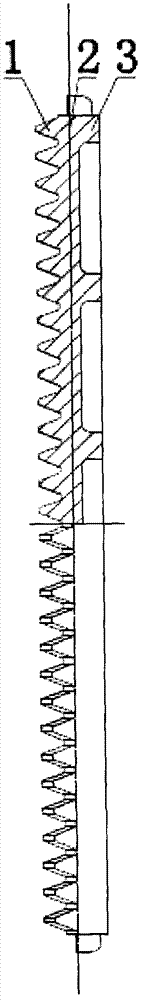

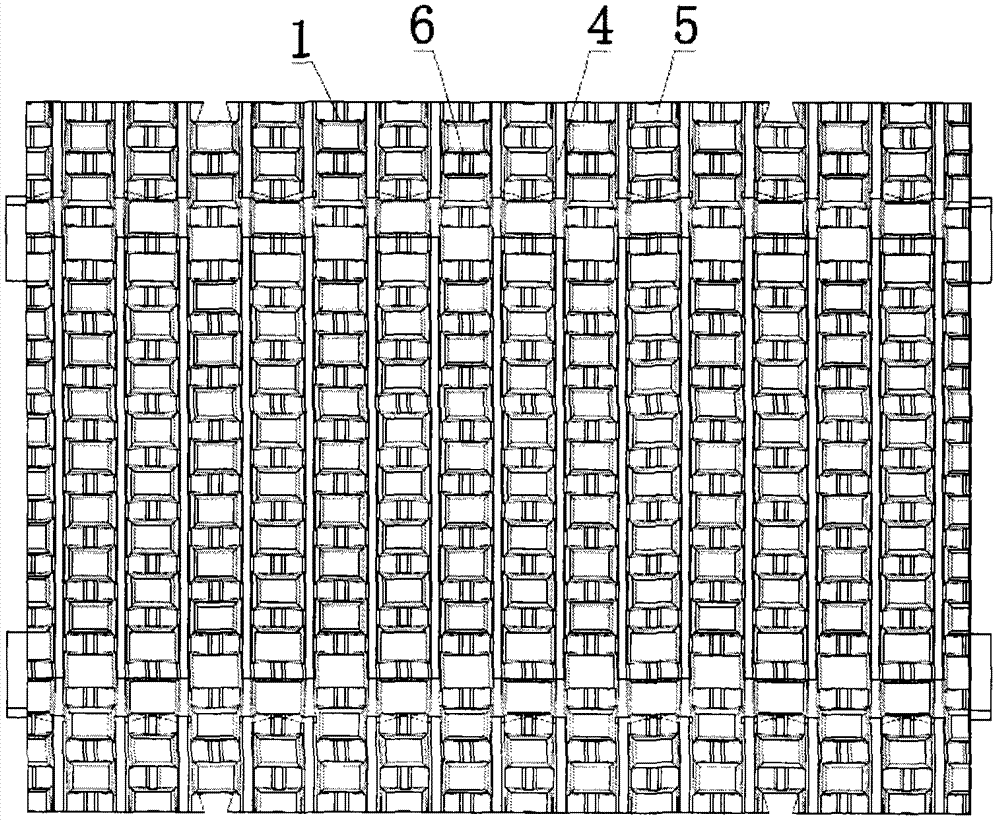

[0052] Embodiment 1: as figure 2 and image 3 As shown, a high-efficiency jaw plate with a rear base is composed of a tooth part 1, a base part 2 and a back part 3, the tooth part 1 is on the front side of the base part 2, the back part 3 is on the back side of the base part 2, and the base part 2 is set at an offset from The center line of the entire jaw is on the 3 sides of the back. There are staggered horizontal tooth peaks 6 and vertical tooth peaks 4 on the tooth portion 1, and tooth valleys 5 between the tooth peaks.

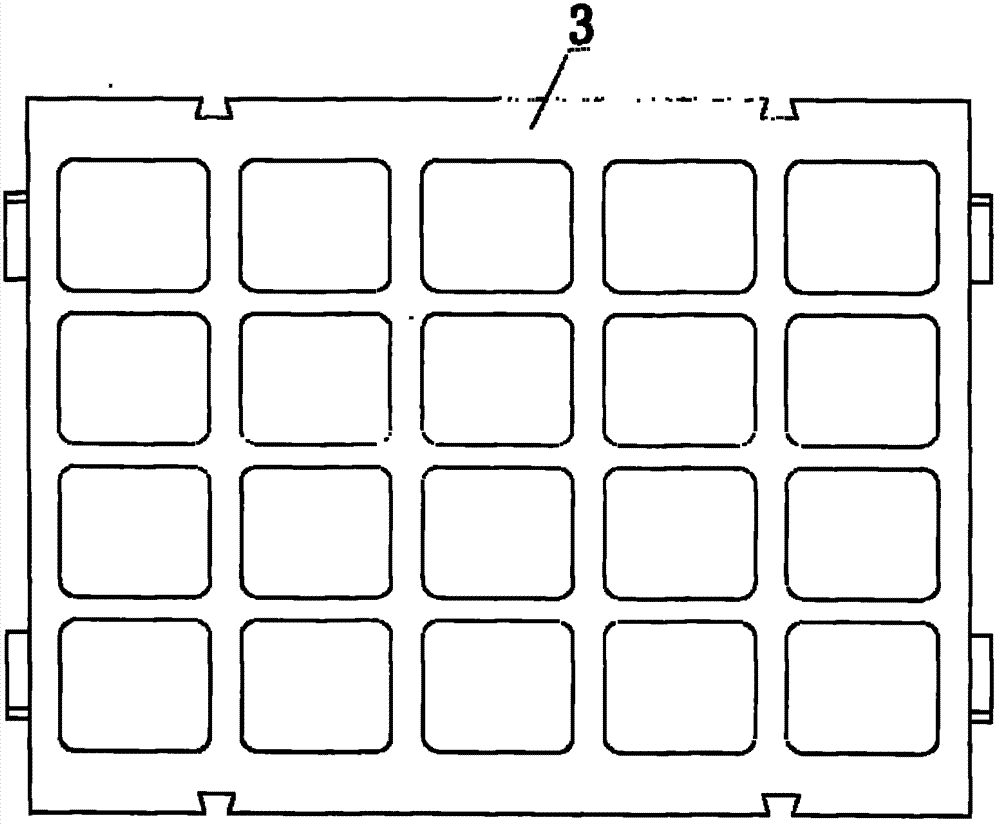

[0053] like Figure 4 As shown, the back 3 is a square frame structure with a thickness of 3 millimeters.

Embodiment 2

[0054] Embodiment 2: as Figure 4 As shown, the back 3 is a matte frame structure, and the thickness is 5 millimeters.

Embodiment 3

[0055] Embodiment 3: as Figure 5 As shown, the back 3 is a groove structure with a depth of 3 mm. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com