Method for optimizing butt-joint position of robot type dust collector in charging and returning process

A technology for robot vacuum cleaners and robots, which is applied in the installation of electrical equipment and other directions, can solve the problems that the vacuum cleaner cannot be successfully docked with the charging base, affect the working efficiency of the robot vacuum cleaner, and the robot vacuum cleaner does not have enough adjustment direction, so as to optimize the charging and return to the docking position, improve the The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

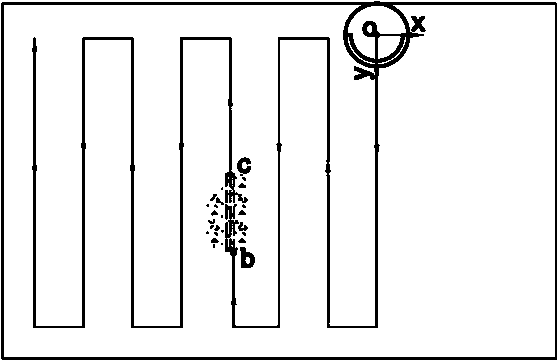

[0030] When the robot vacuum cleaner is cleaning, the robot vacuum cleaner is in an enclosed generally planar area, see image 3 , for cleaning in the comb mode in the X-axis direction or the Y-axis direction, wherein the area outside the inner edge of the closed area is the obstacle area, and the inner area is the cleaning area, wherein the robot vacuum cleaner includes at least one rolling brush, infrared A detection sensor and a dust amount detection sensor arranged at the air inlet of the dust cup.

[0031] The robot vacuum cleaner first walks and cleans along the Y-axis direction. When the infrared detection sensor on the vacuum cleaner detects that there are obstacles such as walls within the set distance in front of walking, the vacuum cleaner moves a displacement amount M1 along the X-axis direction, and then reverses along the Y axis. Axial direction walking cleaning. During the cleaning process, when the robot detects that the amount of dust exceeds the set value, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com