Shoe and shoe sole structure thereof

An outsole and the fourth technology, applied in the field of shoes, can solve the problems of poor wearing comfort, low safety performance of shoes, insufficient shock absorption function of the sole, etc., and achieve the effect of improving the ventilation function and promoting the flow of air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

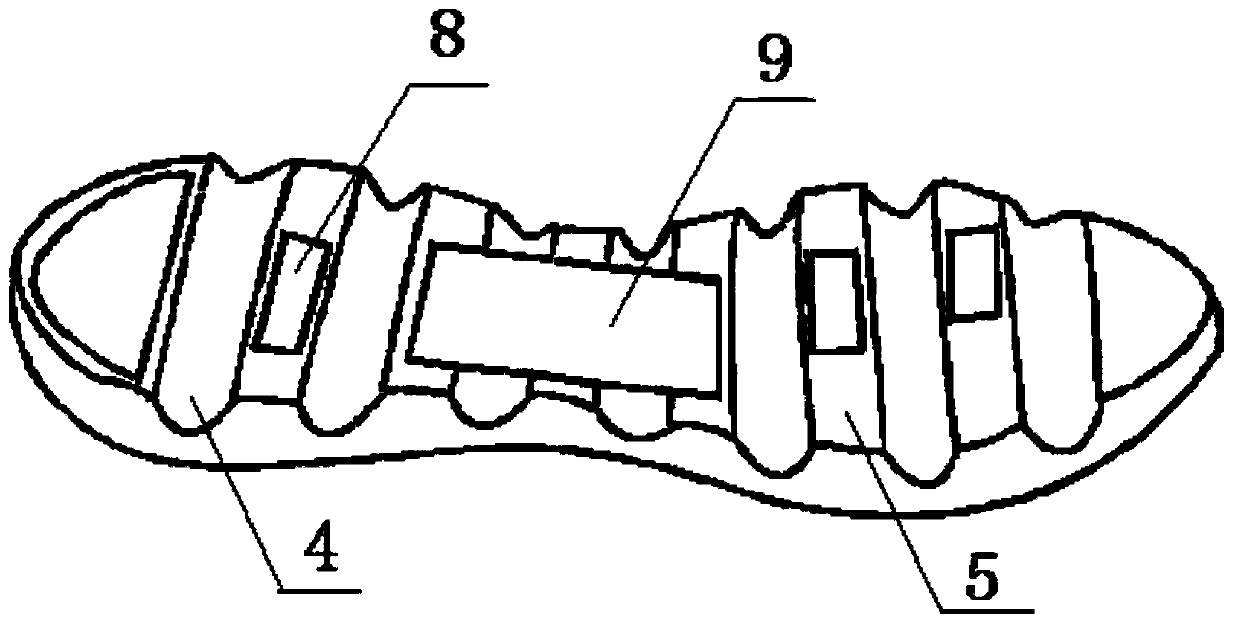

[0033] Embodiment one: if Figure 2-4 As shown, a plurality of the third grooves 8 and the fourth grooves 9 are arranged along the moving track of the center of gravity of the foot during exercise: the moving track of the center of gravity of the foot is from the outside of the heel, through the middle of the heel, the center of the foot, From the middle of the forefoot to the inside of the forefoot.

[0034] The inner side walls of the third groove 8 and the fourth groove 9 are respectively provided with strip-shaped grooves 13 arranged along the length direction of the sole, and the strip-shaped grooves 13 run through the corresponding first ribs respectively. 5. The design of the bar-shaped groove structure helps the deformation of the first groove and the second groove to compress and promote the flow of air and improve the breathability of the sole.

Embodiment 2

[0035] Embodiment two: if Figure 5-7 As shown, the width of the third groove 8 is almost the same as that of the first rib 5 , and the side walls of the fourth groove 9 communicate with the left and right sides of the midsole 2 .

[0036] For the fifth groove 10 corresponding to the third groove 8 and the fourth groove 9 and the upper bottom 3, the lower surface corresponding to the middle part is respectively provided with the second rib 7 The opening groove 14 is provided directly above the opening groove 14 with a ventilation hole 15 penetrating through the upper surface of the upper bottom. The structural design of the opening groove and the ventilation hole helps the deformation of the first groove and the second groove. Compresses and promotes the flow of air, improving the breathability of the sole.

[0037] The present invention overcomes the technical defect that the shock absorption effect of the sole is not obvious due to insufficient deformation of the sole in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com