Soft cheese

A technology of soft cheese and cheese, applied in the field of soft cheese, can solve the problems of not being inoculated with Monascus bacteria, not being inoculated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

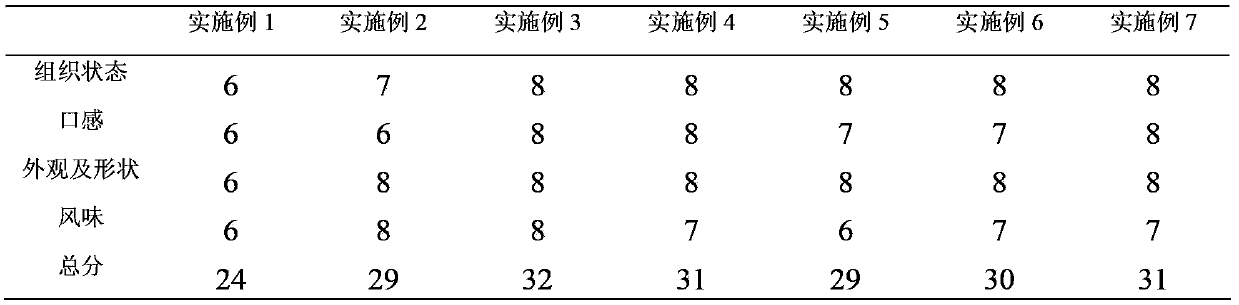

Examples

Embodiment 1

[0011] Embodiment 1: control experiment of white mold mature cheese

[0012] Standardization: The qualified raw milk is standardized so that the ratio of protein to fat is 0.85.

[0013] Pasteurization: pasteurize, heat the milk at 34°C after cooling.

[0014] Lactic acid bacteria fermentation: add 150U / 1000L of lactic acid bacteria starter, carry out acidification fermentation, stir for 5 minutes and then let stand.

[0015] Coagulation with rennet: When the pH of the milk drops by 0.15 units, add 2% (w / v) rennet, and curd the milk for 40 minutes after stirring.

[0016] Drain the whey: cut the curd into 1cm 3 Small pieces, slowly stirred for 50 minutes; 30% whey was discharged, and when the pH value dropped to 5.8, the whey was discharged.

[0017] Mold forming: Add 2.5% salt, put into the mold, and turn over regularly.

[0018] Inoculation: the curd block is taken out from the mould, cut into cheese cubes with a thickness of 3.5cm, and sprayed with the mixed bacterial l...

Embodiment 2

[0024] Manufacturing method of white mold red koji mixed mature cheese

[0025] Standardization: The qualified raw milk is standardized so that the ratio of protein to fat is 0.8.

[0026] Pasteurization: pasteurize, heat the milk at 32°C after cooling.

[0027] Lactic acid bacteria fermentation: add 100U / 1000L of lactic acid bacteria starter, carry out acidification fermentation, stir for 5 minutes and then let stand.

[0028] Rennet curdling: When the pH of the milk drops by 0.15 units, add rennet 2% (w / v), and curd the milk for 30 minutes after stirring.

[0029] Drain the whey: cut the curd into 1cm 3 Small pieces, slowly stirred for 15 minutes; 30% whey was discharged, and when the pH value dropped to 5.5, the whey was discharged.

[0030] Mold forming: add 2% salt, put into the mold, and turn over regularly.

[0031] The first inoculation: Take the curd block out of the mold, cut it into cheese cubes with a thickness of 2cm, spray the Monascus liquid, turn the cheese...

Embodiment 3

[0035] Embodiment 3: white mold red koji mixed mature cheese

[0036] Standardization: The qualified raw milk is standardized so that the ratio of protein to fat is 0.85.

[0037] Pasteurization: pasteurize, heat the milk at 34°C after cooling.

[0038] Lactic acid bacteria fermentation: add 150U / 1000L of lactic acid bacteria starter, carry out acidification fermentation, stir for 5 minutes and then let stand.

[0039] Coagulation with rennet: When the pH of the milk drops by 0.15 units, add 2% (w / v) rennet, and curd the milk for 40 minutes after stirring.

[0040] Drain the whey: cut the curd into 1cm 3 Small pieces, stirred slowly for 50min. Discharge 30% whey, when the pH value drops to 5.8, the whey is discharged.

[0041] Mold forming: Add 2.5% salt, put into the mold, and turn over regularly.

[0042] The first inoculation: take the curd block out of the mold, cut it into cheese cubes with a thickness of 3.5cm, and spray the Monascus liquid. Turn the cheese every d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com