A kind of blowing roller machine

A drum machine and drum technology, applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problem of single function of the blowing machine and the inability to realize the dual functions of blowing and sediment separation, etc. problem, to achieve a reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

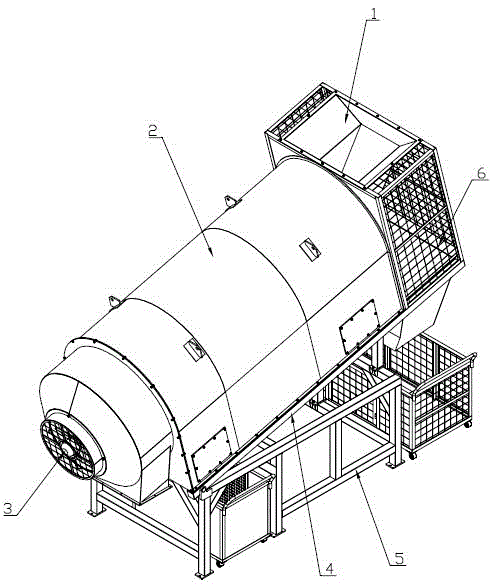

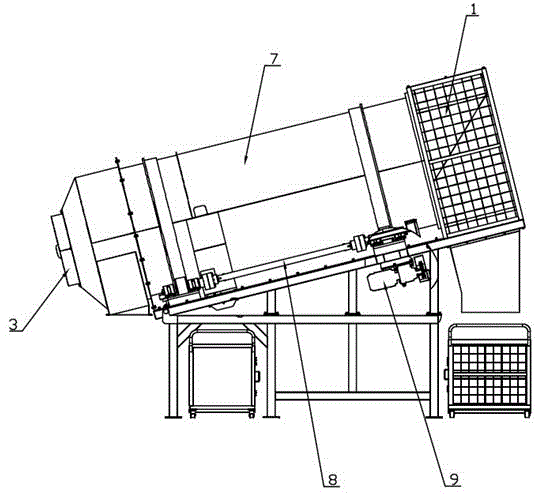

[0026] In this example, if figure 1 and figure 2 As shown, the present invention includes a reducer 9, a support, a drum 7, a machine cover 2, a hopper 1, a hopper and a fan 3; the bracket includes a lower bracket 5 and a drum bracket 4; the drum bracket 4 is provided with a main drive combination 8 It is combined with the driven transmission (not marked on the figure); the reducer 9 is connected with the main transmission combination 8; the hood 2 covers the entire drum machine device; the feeding hopper 1 is set at the entrance of the drum 7, and the fan 3 is set at the drum 7 of the exit. The roller support 4 is an inclined support, and then the cylinder 7 is placed on the roller support 4 and is also in an inclined state. The upwardly inclined end is the upper end of the cylinder, and the downwardly inclined end is the lower end of the cylinder.

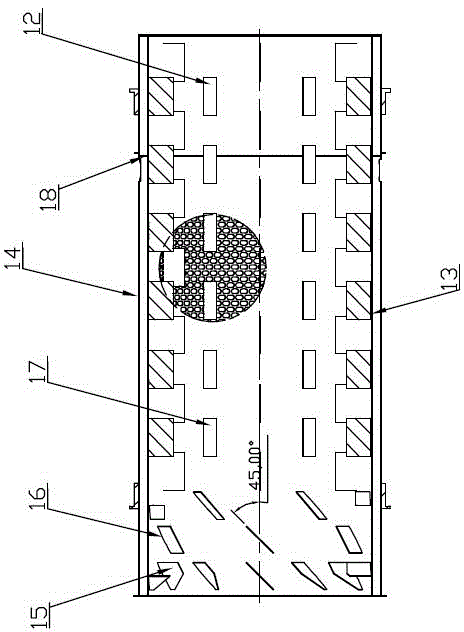

[0027] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com