A device for crushing nitrocellulose-absorbed drug clusters or drug blocks

A crushing device and drug absorption technology, applied in grain processing, etc., to achieve the effect of simple process, uniform size and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention are provided below, and the technical solutions of the present invention are not limited to the following specific embodiments, and all equivalent transformations performed on the basis of the technical solutions of the present invention are within the protection scope of the present invention.

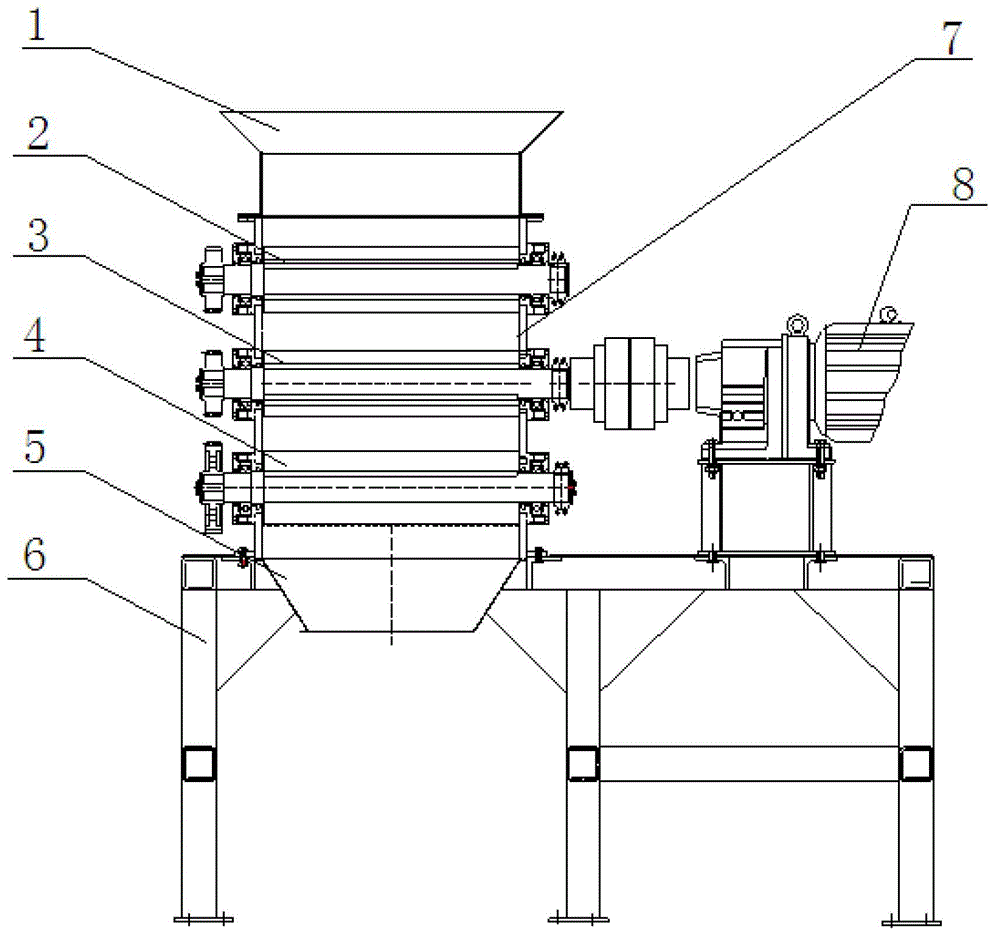

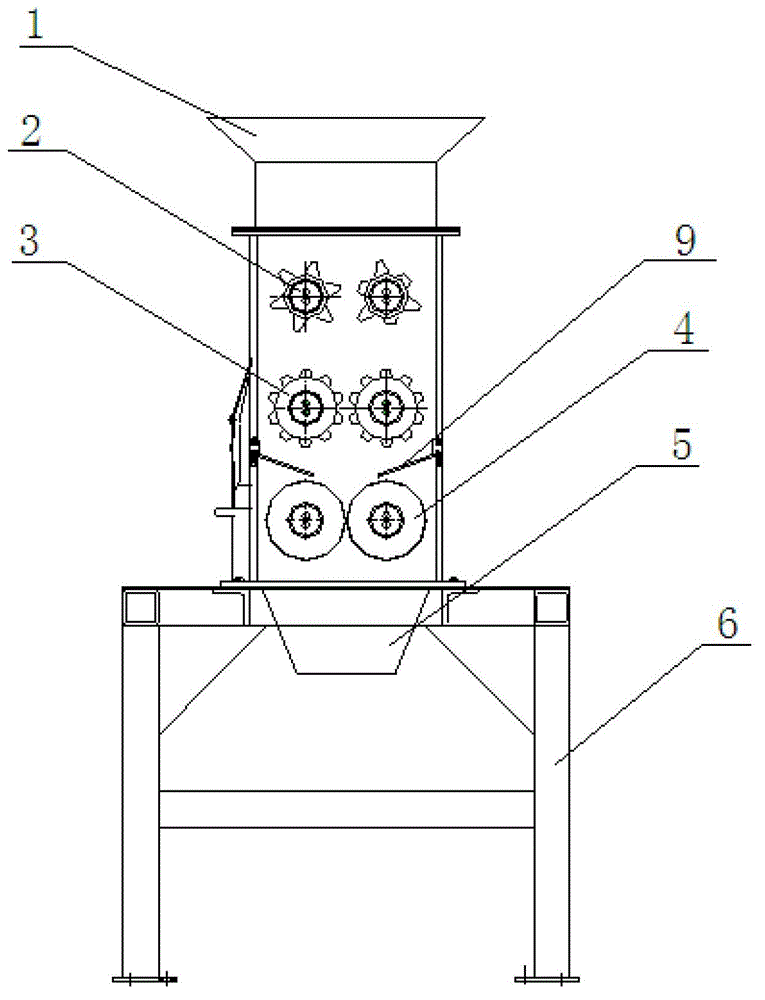

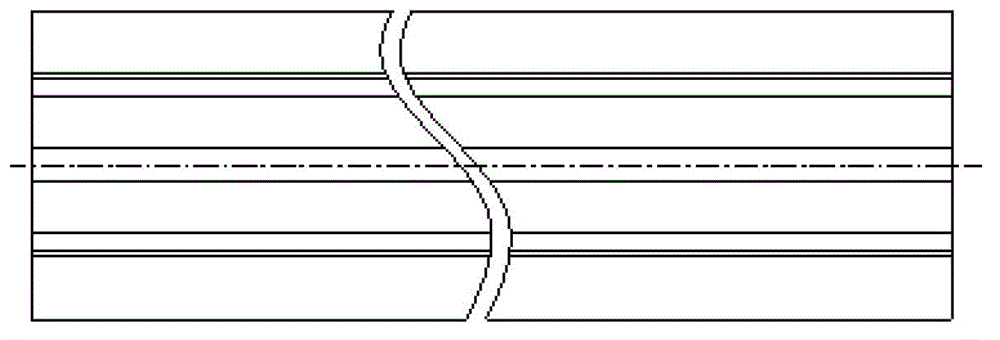

[0023] Comply with the above technical solutions, such as figure 1 and figure 2 Shown, a kind of nitrocellulose absorbs medicine group or medicine block crushing device, comprises frame 6, and vertical medicine box 7 is installed on the frame 6, is provided with motor 8 on the frame 6 of medicine box 7 side; The top of the above-mentioned medicine box 7 is provided with a hopper 1, and the bottom of the medicine box 7 is provided with a discharge port 5. In the medicine box 7, there are three stages of crushing mechanisms arranged sequentially from top to bottom: the first stage crushing mechanism 2, the second stage crushing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com