White tea processing technology

A processing technology, white tea technology, applied in the field of white tea processing technology, can solve the problems of lack of "pretreatment" technology in tea making process, reduction of finished white tea extract, low production efficiency, etc., to improve the overall effective utilization rate, eliminate low Tea polyphenol content, cycle-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

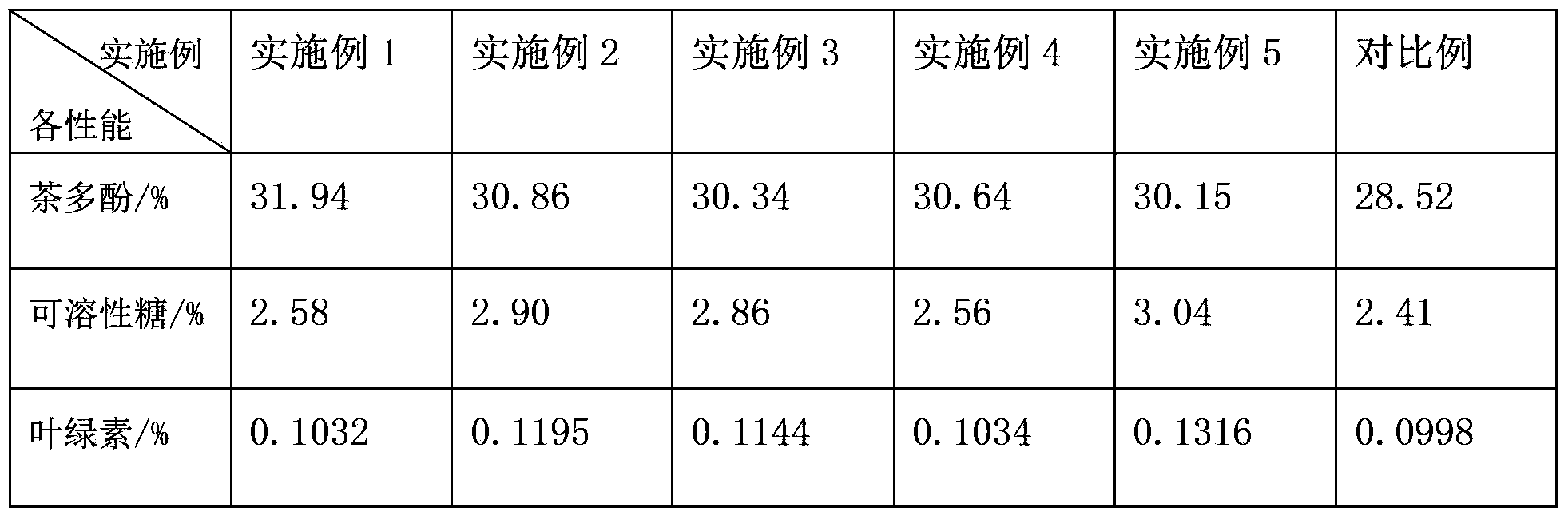

Examples

Embodiment 1

[0022] A kind of white tea processing technology, its step comprises as follows:

[0023] (1) Picking fresh leaves: Picking fresh leaves of tea trees with "one bud and one leaf, one bud and two leaves";

[0024] (2) Pretreatment: Place the fresh leaves after acceptance in a constant temperature room, and spray 0.4% endoglucanase and 0.2% pectinase at a mass concentration of 0.4% at 50°C. The spraying speed is uniform, and the spraying flow rate is 200ml per minute; processing time is 0.5h:

[0025] (3) Airing green: Spread the pretreated fresh leaves evenly on soft plaques or bamboo mats with a thickness of 2cm. The relative humidity of the air in the spreading room is controlled at 90%, the room temperature is controlled at 15°C, and the leaf temperature is controlled at Within 30°C, for 2 hours, spread the fresh leaves until the leaves are soft, the tender stems are constantly folded, and a light fragrance is enough;

[0026] (4) Greening: Put the dried fresh leaves into t...

Embodiment 2

[0031] A kind of white tea processing technology, its step comprises as follows:

[0032] (1) Picking fresh leaves: Picking fresh leaves of tea trees with "one bud and one leaf, one bud and two leaves";

[0033] (2) Pretreatment: Place the fresh leaves after acceptance in a constant temperature room, and spray 0.3% endoglucanase and 0.3% pectinase at a mass concentration of 0.3% at 55°C. The spraying speed is uniform, and the spraying flow rate is Minute 120ml, processing time is 1h:

[0034] (3) Airing: spread the pretreated fresh leaves evenly on a soft plaque or bamboo mat with a thickness of 3 cm. The relative humidity of the air in the spreading room is controlled at 95%, the room temperature is controlled at 20°C, and the leaf temperature is controlled at Within 30°C, for 3 hours, spread the fresh leaves until the leaves are soft, the tender stems are constantly broken, and a light fragrance is enough;

[0035] (4) Greening: put the dried fresh leaves into the drum gre...

Embodiment 3

[0040] A kind of white tea processing technology, its step comprises as follows:

[0041] (1) Picking fresh leaves: Picking fresh leaves of tea trees with "one bud and one leaf, one bud and two leaves";

[0042] (2) Pretreatment: Place the fresh leaves after acceptance in a constant temperature room, and spray 0.35% endoglucanase and 0.25% pectinase at a mass concentration of 53°C. The spraying speed is uniform, and the spraying flow rate is Minute 150ml, processing time is 0.8h:

[0043] (3) Airing: spread the pretreated fresh leaves evenly on a soft plaque or bamboo mat with a thickness of 2 cm. The relative humidity of the air in the spreading room is controlled at 90%, the room temperature is controlled at 18°C, and the leaf temperature is controlled at Within 30°C, for 2.5 hours, spread the fresh leaves until the leaves are soft, the tender stems are constantly broken, and a light fragrance is enough;

[0044] (4) Greening: Put the dried fresh leaves into the drum green...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com