Fully automatic low-voltage current transformer test wiring device

A low-voltage current and wiring device technology, which is applied in the field of automatic low-voltage current transformer testing wiring devices, achieves the effects of good reliability, simple wire removal process and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

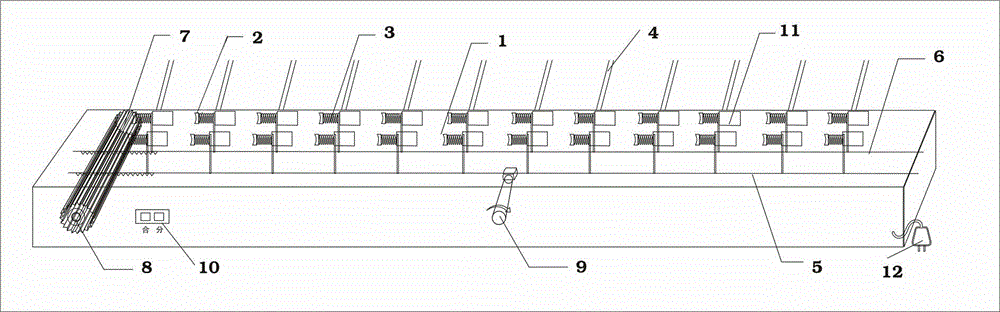

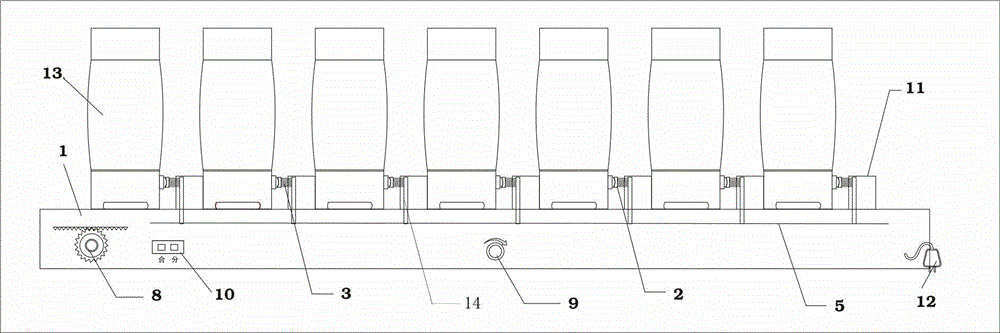

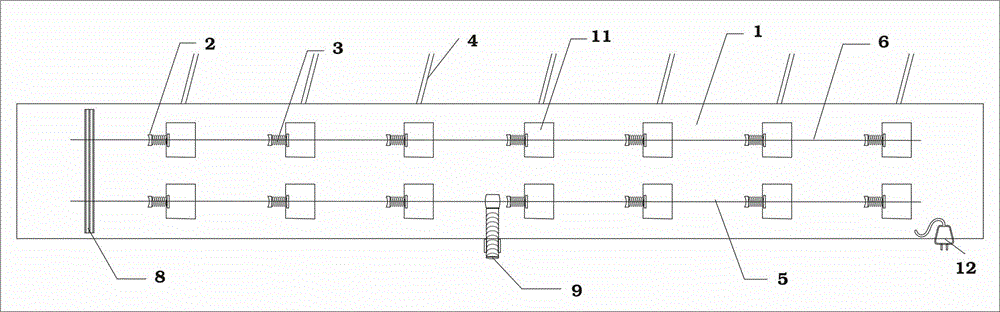

[0015] Such as figure 1 As shown, the automatic low-voltage current transformer test wiring device of the present invention includes a steel insulating shell 1, a test contact 2, a spring 3, a test lead wire 4, a transmission main shaft 5, a transmission main shaft 6, a driving wheel 8, a fixed gear Plate 11, power source and transmission mechanism, transmission main shaft 5, 6 are arranged in parallel in the insulating shell 1, and driving wheel 8 is installed below one end of two transmission main shafts, and driving wheel 8 has gear tooth 7, and gear tooth 7 is connected with transmission main shaft The gear teeth of the bottom of 5 and 6 drive two transmission main shafts to move simultaneously. The driving wheel is connected to the motor through the transmission mechanism, and the motor is connected to the control switch 10 and the device power supply 12 through the circuit. The transmission spindles 5 and 6 are each provided with several vertical columns 14, and the insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com