A special contact for high voltage circuit breaker test

A high-voltage circuit breaker, cylindrical technology, applied in the field of special contacts for high-voltage circuit breaker testing, can solve the problems of missing test lines and short-circuits, misjudging the true state of equipment, burnt contacts, etc., and achieves convenient and quick connection and removal. , Accurate test data, easy to use and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

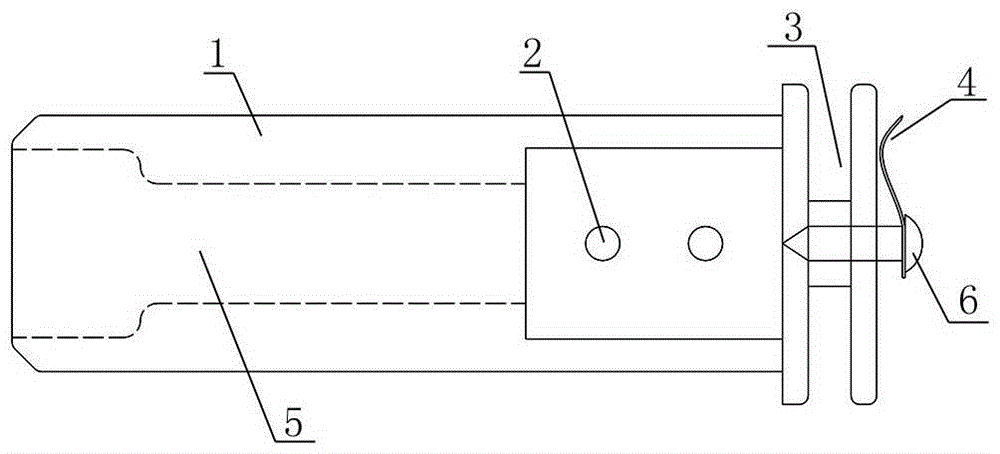

[0019] figure 1 , 2 As shown, the cylindrical body 1 of the special contact for high voltage test is made of brass casting, and the inside of one end is a hollow hole. The bare copper wire clamping groove 3 is a groove on the body 1 near the bottom of one end.

[0020] When testing a high-voltage circuit breaker, insert the special body 1 for high-voltage circuit breaker testing into the static contact of the high-voltage circuit breaker, and connect the high-voltage test line that needs to be clamped to the static contact of the high-voltage circuit breaker to the special high-voltage circuit breaker test. The special jack 2 for the maintenance test line of the main body 1, or clamp it to the special main body 1 for the high-voltage circuit breaker test with a large clamp for testing. Use the short-circuited bare copper wire clamping spring piece 4 to directly clamp it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com