Moso bamboo dividing machine

A moso bamboo splitting machine and splitting machine technology are applied to mechanical equipment, sugarcane machining, and processing machines for manufacturing flat surfaces, etc., which can solve the problems of time-consuming and laborious operation, low work efficiency, and large floor space, and achieve high efficiency, Reduced burr rate and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the various embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments described in the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts are within the protection scope of the present invention.

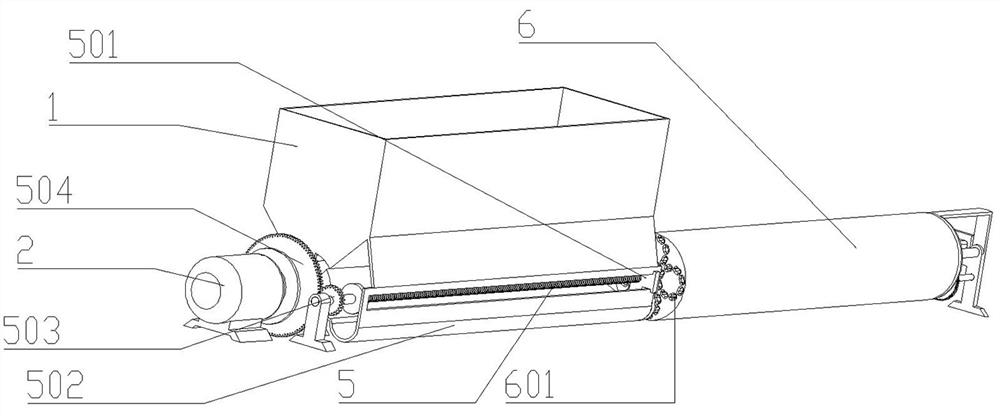

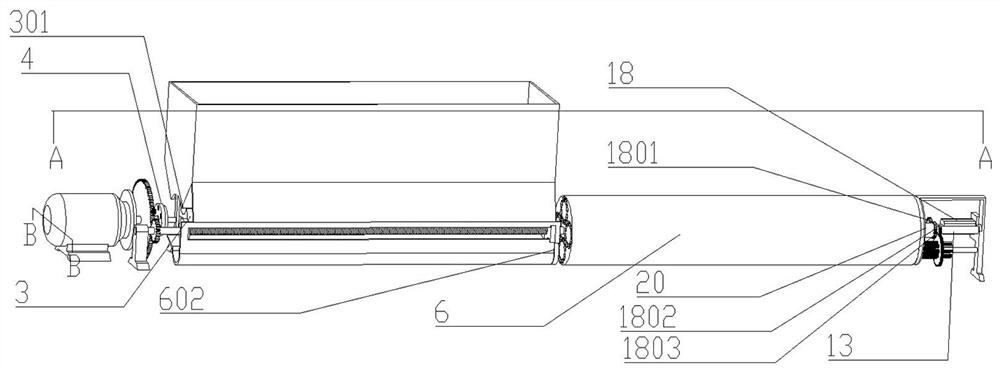

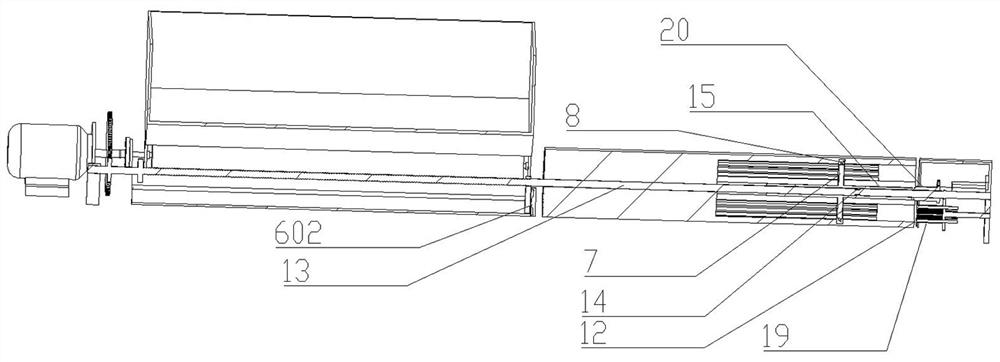

[0033] Embodiments of the present invention provide a kind of bamboo cutting machine, such as Figure 1-8As shown, it includes a feeding mechanism driven by the same first power source, a propulsion mechanism, a rough planing mechanism, and a dividing mechanism; The slitting blades 602 of eight bamboo strips; the rough planing mechanism includes a rough planing housing 6, a rotating shaft 13, and the rotating shaft 13 is provided with a cam groove 14, and the cam groove 14 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com