Preparation method of squid liver paste

A technology of squid paste and squid, which is applied in the field of squid paste, can solve the problems of increased histamine, uncontrollable poor flavor, and no fluidity, and achieves the effects of stable flavor, improved appearance and fluidity, and reduced histamine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Mix 10kg of fresh squid processed scraps with no less than 50% of the squid viscera (55% of the squid entrails) and glutamic acid. The amount of glutamic acid is 0.5% (0.035kg) of the dry matter weight of the squid processed scraps. ). Incubate at 40°C, stir and react for 1 hour, and use its own enzymes to perform enzymatic hydrolysis; add xylose to 0.2% (0.014kg) of the dry matter weight of the enzymatic hydrolysate, and concentrate it to a paste with a water content of 45% after enzymatic hydrolysis. That is the finished product.

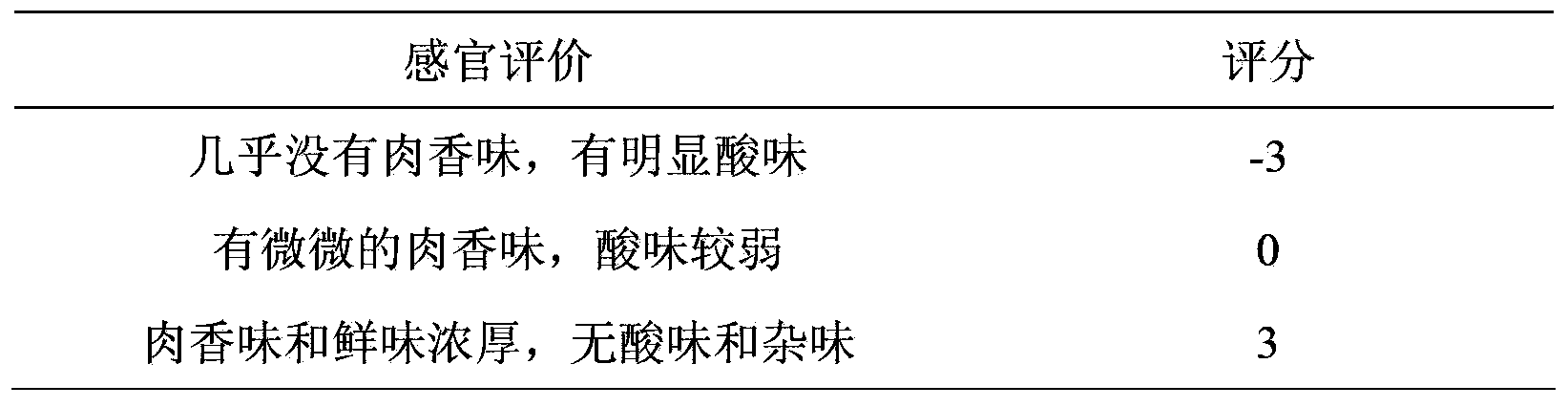

[0033] Sensory evaluation of the obtained squid paste was carried out. The sensory evaluation adopted the principle of comprehensive scoring. Each group of test samples were scored by 11 scorers. After improvement, they were brown, with a relatively uniform color, and a clear meat flavor with a slight burnt taste. Fishy and other peculiar smells, the overall fragrance is relatively plump and pure, and the fragrance is rich and natural. The s...

Embodiment 2

[0040] Combine 10kg of squid processing scraps with no less than 50% of the squid viscera (51% of the squid viscera content) and glutamic acid, and the amount of glutamic acid is 3% (0.21kg) of the dry matter weight of the squid processing scraps ), incubate at 65°C, stir and react for 6 hours, use its own enzyme for enzymatic hydrolysis; add xylose (0.14kg) to the enzymatic hydrolysate at 2% of the dry matter weight, and concentrate to a paste with 45% water content after enzymatic hydrolysis , Which is the finished product.

[0041] Sensory evaluation of the obtained squid paste: The sensory evaluation adopts the principle of comprehensive scoring, and 11 raters score each group of test samples. After improvement, they are brown, uniform in color, and have obvious meat flavor, without burning or fishy smell. The overall fragrance is relatively plump and pure, and the fragrance is rich and natural, with a score of 2.8. The improvement effect is better.

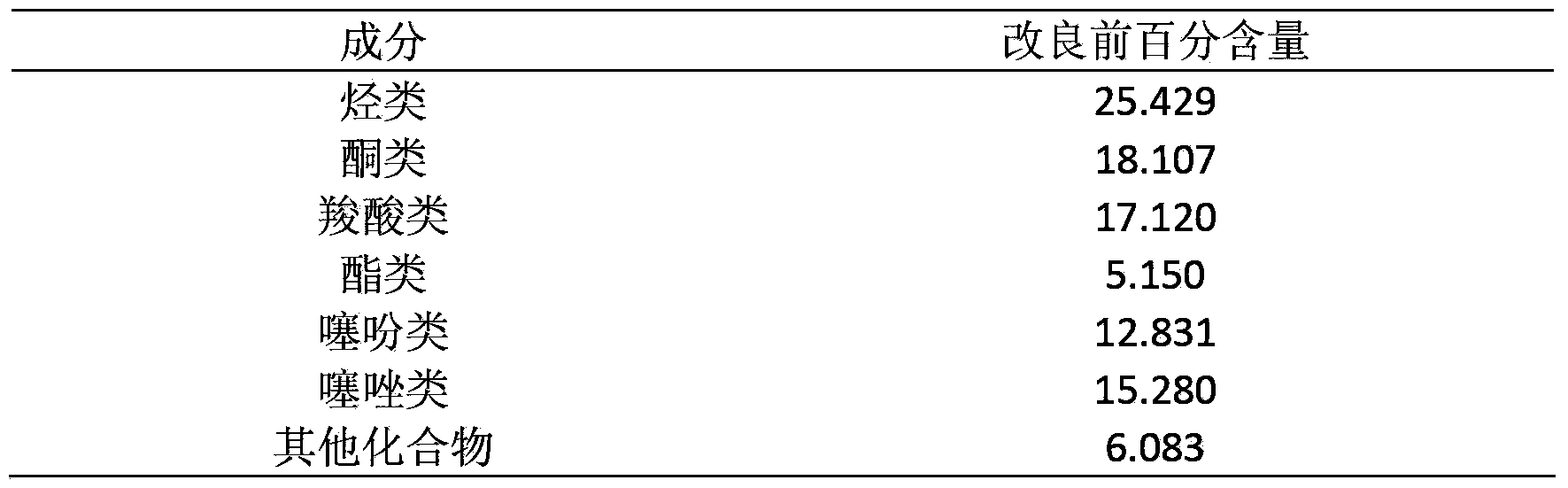

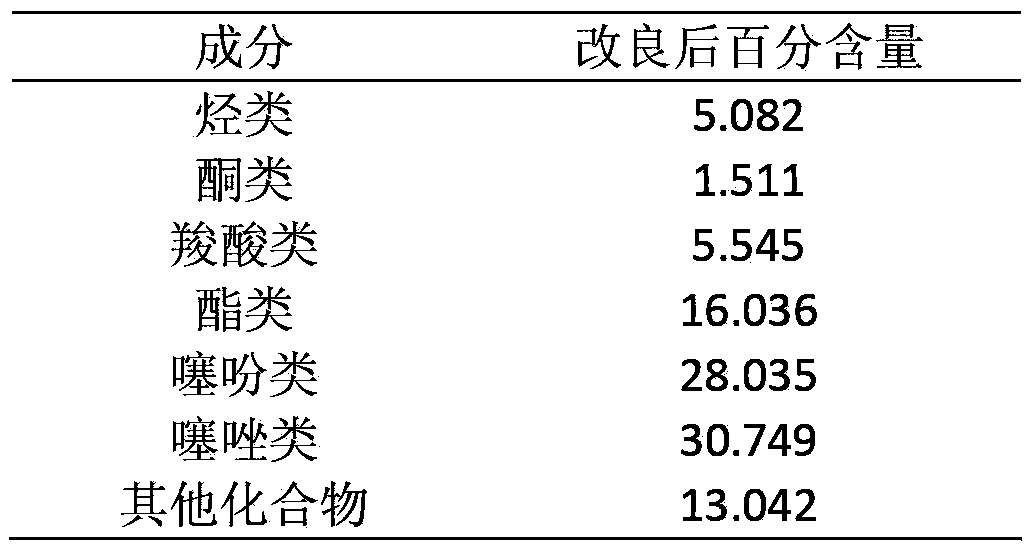

[0042] The volatile comp...

Embodiment 3

[0048] Combine 10kg of squid processing scraps with no less than 50% of the squid viscera (55% of the squid viscera content) and glutamic acid, and the amount of glutamic acid shall be 2% (0.14kg) of the dry matter weight of the squid processing scraps ), keep at 50°C, stir and react for 3 hours, use its own enzymes for enzymatic hydrolysis; add xylose (0.07kg) to the enzymatic hydrolysate according to 1% of the dry matter weight, and concentrate to a paste with 45% water content after enzymatic hydrolysis , Which is the finished product.

[0049] Sensory evaluation of the obtained squid paste: The sensory evaluation adopts the principle of comprehensive scoring, and 11 scorers will score each group of test samples. After improvement, they are brown, with a relatively uniform color, and a relatively obvious meat flavor, without burnt smell. Fishy and other peculiar smells, the overall fragrance is very plump and pure, and the aroma is rich and natural, with a score of 2.7. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com