Film-forming apparatus

A film-forming device and film-forming technology, applied in lighting devices, ion implantation plating, coating, etc., can solve problems such as chamber deformation increase, waste, evaporation pattern deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

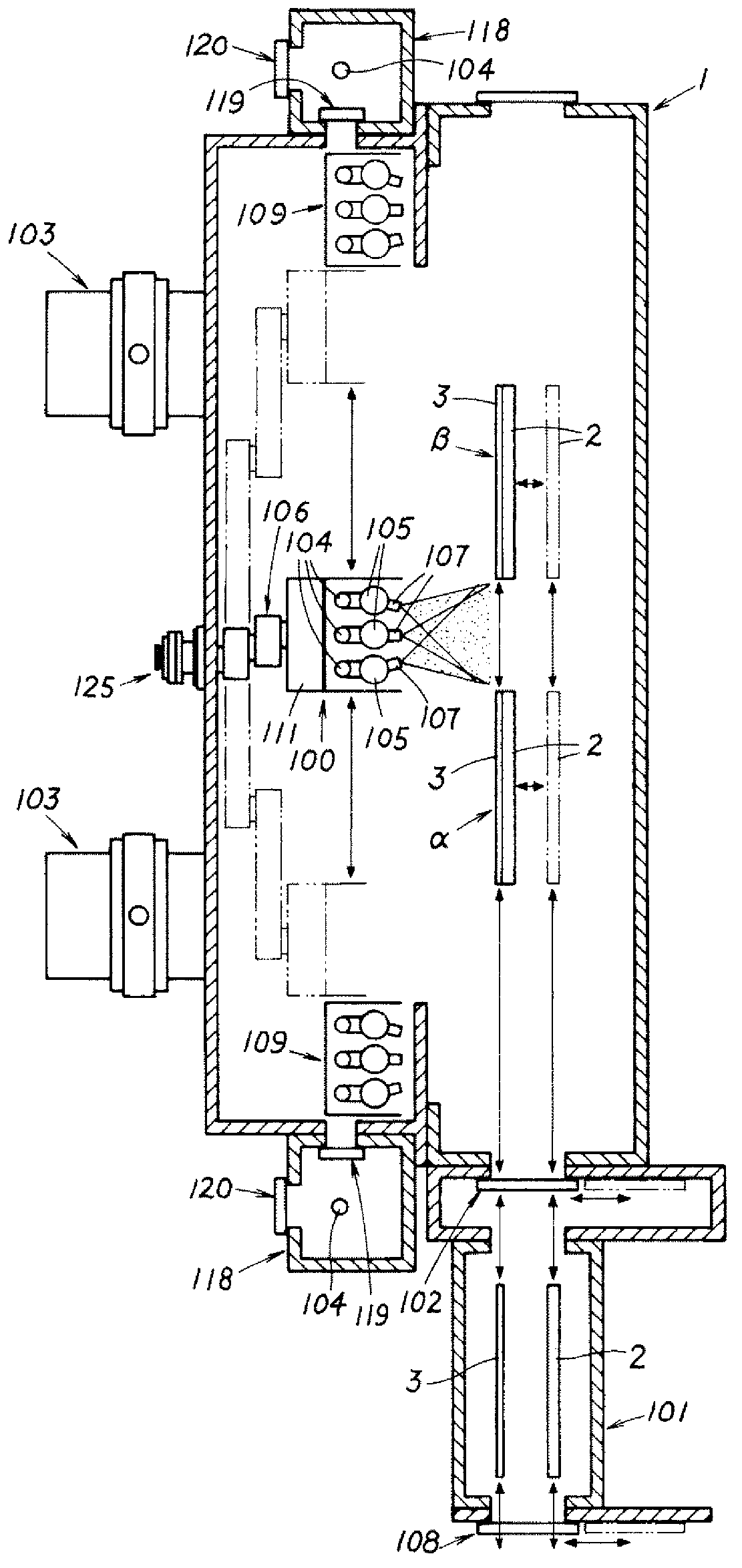

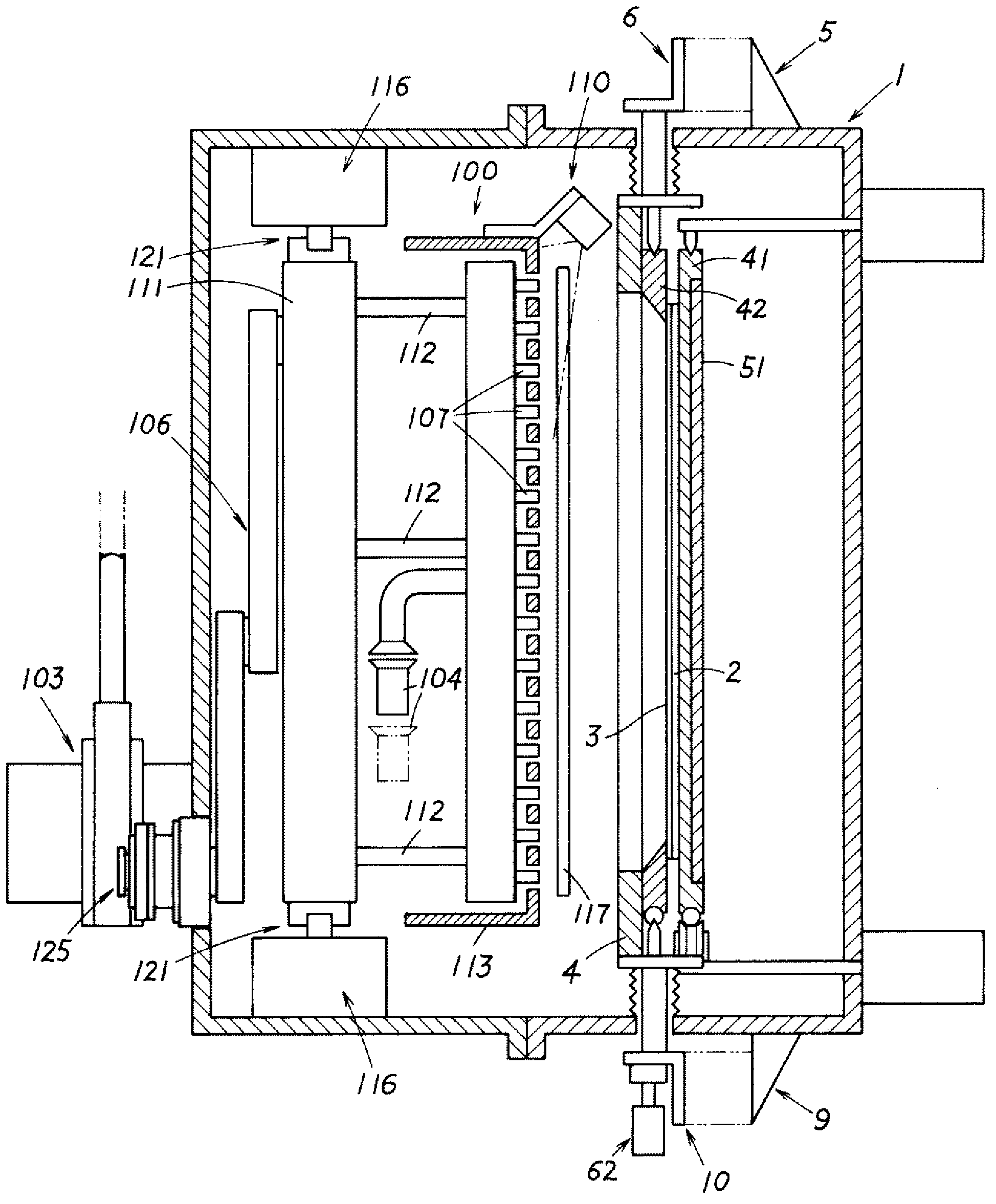

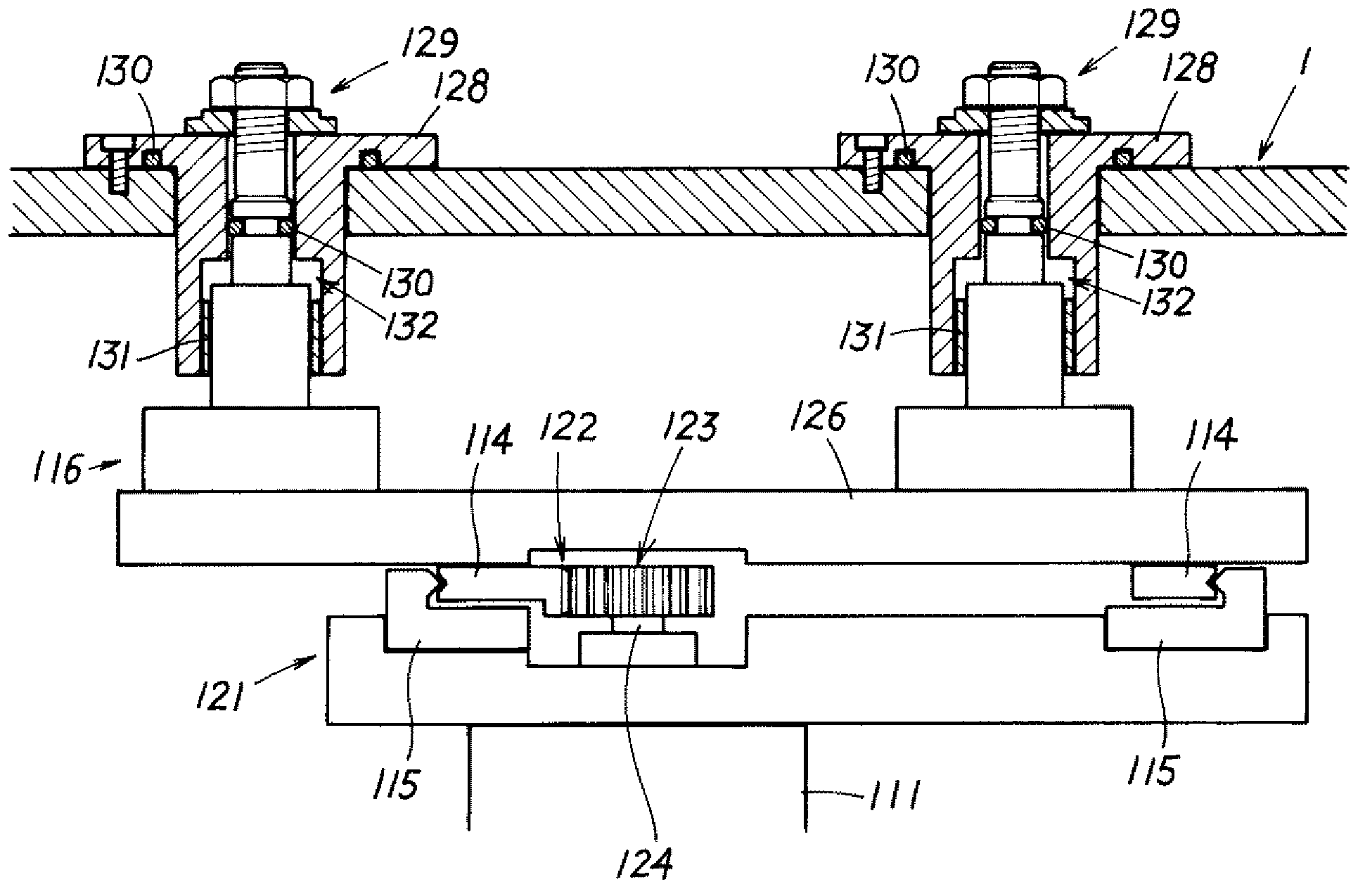

[0082] Specific embodiments of the present invention will be described based on the drawings.

[0083] This embodiment is an embodiment in which the present invention is applied to a film-forming chamber of a film-forming apparatus (vacuum deposition apparatus) equipped with a vertically erect state conveyance (vertical conveyance chamber) that stands vertically with respect to the horizontal direction. ) Substrate transfer mechanism and mask transfer mechanism for substrate 2 and mask 3 .

[0084] That is, the present embodiment is a film forming apparatus including a film forming chamber 1 in which a film forming material is attached to a substrate 2 held in an upright state via a mask 3 to perform For film formation, the film formation chamber 1 is provided with: an alignment driving mechanism, which makes the alignment frame 4 which installs the mask 3 in an upright state move relative to the substrate 2 to adjust and move the mask 3 Alignment with the substrate 2, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com