A multifunctional energy storage device integrating energy storage and structure and its preparation method

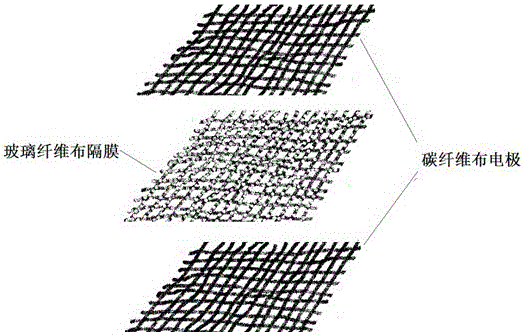

An energy storage device and multi-functional technology, which can be applied in the manufacture of hybrid/electric double layer capacitors, separators of hybrid capacitors, electrodes of hybrid capacitors, etc. problems, to achieve the effect of increasing tensile strength and surface activity, increasing effective specific surface area and surface activity, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Activation treatment of carbon fiber cloth

[0034] ① Carbon fiber cloth deglue treatment

[0035] Using acetone and ethanol as a solvent with a volume ratio of 1:2, soak polyacrylonitrile-based carbon fiber cloth for 24 hours, then wash it with deionized water, and dry it at 80°C for 12 hours.

[0036] ② Liquid phase oxidation of carbon fiber cloth

[0037] Clean the polyacrylonitrile-based carbon fiber cloth with deionized water ultrasonically for 30 minutes, and immerse it in KClO with a volume ratio of 1:1. 3 with H 2 SO 4 In the mixed solution of KClO 3 Concentration is 5%, H 2 SO 4 The concentration is 40%, carbon fiber cloth and KClO 3 with H 2 SO 4 The mass ratio of the mixed solution is 1:80, stir, heat, and treat the carbon fiber cloth at 60°C for 3h; take out the oxidized carbon fiber cloth and wash it with deionized water until neutral, put it in a blast drying oven at 80°C for 12h .

[0038] ③Gas-phase oxidation of carbon fiber cloth

[0039...

Embodiment 2

[0047] (1) Activation treatment of carbon fiber cloth

[0048] ① Carbon fiber cloth deglue treatment

[0049] Using acetone and ethanol as a solvent with a volume ratio of 1:2, soak polyacrylonitrile-based carbon fiber cloth for 24 hours, then wash it with deionized water, and dry it at 80°C for 12 hours.

[0050] ② Liquid phase oxidation of carbon fiber cloth

[0051] Clean the polyacrylonitrile-based carbon fiber cloth with deionized water ultrasonically for 30 minutes, and immerse it in KClO with a volume ratio of 1:1. 3 with H 2 SO 4 In the mixed solution of KClO 3 Concentration is 10%, H 2 SO 4 The concentration is 30%, carbon fiber cloth and KClO 3 with H 2 SO 4 The mass ratio of the mixed solution is 1:80, stir, heat, and treat the carbon fiber cloth at 80°C for 2 hours; take out the oxidized carbon fiber cloth and wash it with deionized water until it is neutral, and dry it in a blast drying oven at 80°C for 12 hours .

[0052] ③Gas-phase oxidation of carbon...

Embodiment 3

[0061] (1) Activation treatment of carbon fiber cloth

[0062] ① Carbon fiber cloth deglue treatment

[0063] Using acetone and ethanol as a solvent with a volume ratio of 1:2, soak polyacrylonitrile-based carbon fiber cloth for 24 hours, then wash it with deionized water, and dry it at 80°C for 12 hours.

[0064] ② Liquid phase oxidation of carbon fiber cloth

[0065] Clean the polyacrylonitrile-based carbon fiber cloth with deionized water ultrasonically for 30 minutes, and immerse it in KClO with a volume ratio of 1:1. 3 with H 2 SO 4 In the mixed solution of KClO 3 Concentration is 15%, H 2 SO 4 The concentration is 20%, carbon fiber cloth and KClO 3 with H 2 SO 4 The mass ratio of the mixed solution is 1:80, stir, heat, and treat the carbon fiber cloth at 100°C for 1 hour; take out the oxidized carbon fiber cloth and wash it with deionized water until it is neutral, put it in a blast drying oven and dry it at 80°C for 12 hours .

[0066] ③Gas-phase oxidation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com