High-voltage test junction pole

A high-voltage test and wiring rod technology, which is applied in the direction of the measuring device shell, can solve the problems of personal safety hazards for operators, difficulty in fixing the top, and falling off of test lines, so as to reduce potential safety hazards and prevent floating instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

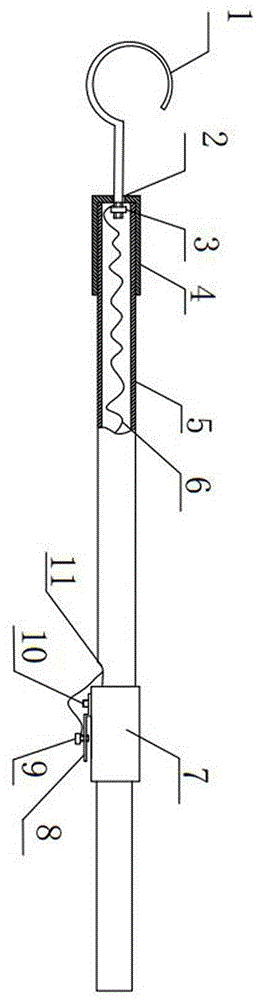

[0014] Depend on figure 1 It can be seen that the high-voltage test wiring rod includes an insulating rod 5 and a hook 1. The insulating rod 5 is a hollow rod, and its upper end is provided with a first connecting sleeve 4 with a closed end. The closed end of the first connecting sleeve 4 is provided with a central hole 2; the hook 1 includes a suspension hook and a straight rod, and the end of the straight rod is provided with threads, and the end of the straight rod of the hook 1 passes through the central hole 2 of the first connecting sleeve 4 and penetrates into the insulating rod 5, from the insulation The test lead 6 passing through the inside of the rod 5 is fixedly connected with the hook 1 through the nut 3 .

[0015] Preferably, the side of the lower end of the insulating rod 5 is provided with an outlet hole 11, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com