Common mechanical press wet-type clutch universal test tooling

A mechanical press and wet clutch technology, applied in the field of workpiece clamping, can solve the problems of low work efficiency, large number of tooling and high production cost, and achieve the effect of convenient debugging and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

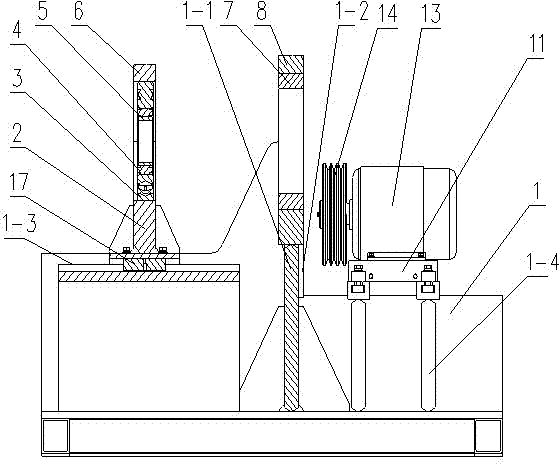

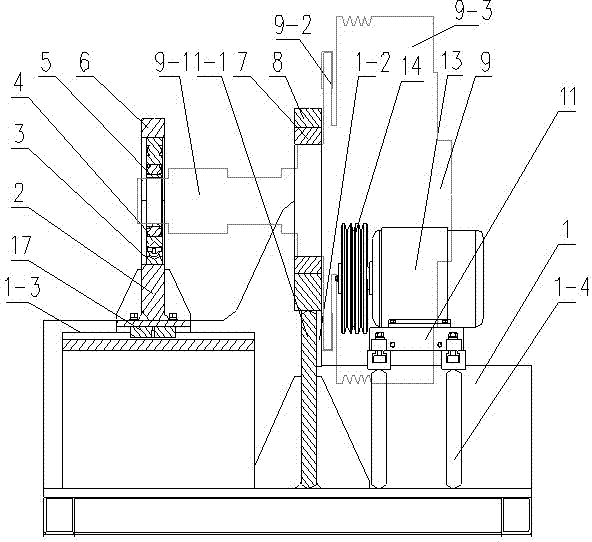

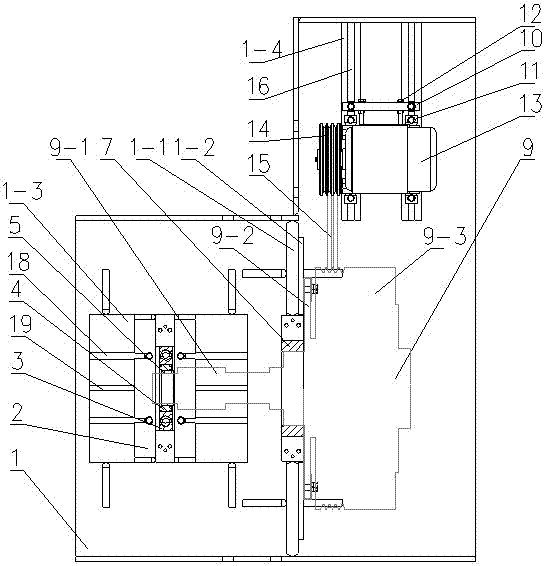

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] Such as Figure 1 to Figure 3 As shown, the common mechanical press wet clutch general test tooling includes a base body 1, a bracket 2, a large support plate 1-1 and a motor 13 equipped with a pulley 14, and the bracket 2 and the large support plate 1-1 are located on the base body 1 respectively. the rear and middle positions (in figure 1 The right side is the front direction, the same below), the bearing 3 and the upper cover II6 are installed on the bracket 2, the upper cover I8 is installed on the large support plate 1-1, and the platform 1-3 is also included, and the platform 1-3 is equipped with a bracket 2 Two vertical T-shaped slots Ⅱ18, the bracket 2 is installed on the platform 1-3 through the T-shaped slots Ⅱ18, and the inner side of the bearing 3 on the bracket 2 is also equipped with an expansion sleeve 4 and an adjustment sleeve 5 in sequence; the lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com