Sliding force detection device used for air disc brake

A disc brake and detection device technology, which is applied in the direction of measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems of inability to fully guarantee the reliability of detection results and low efficiency, and achieve stable and reliable detection results. Accurate trajectory and precise production effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

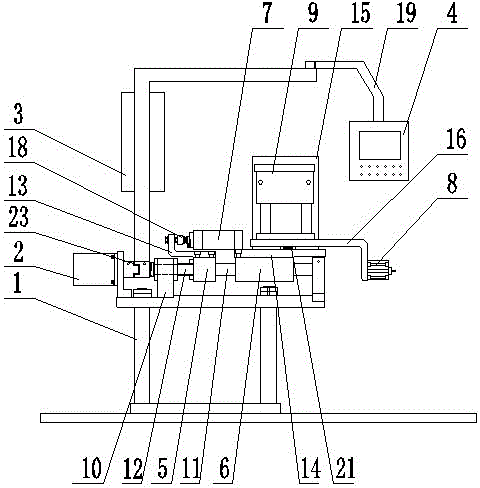

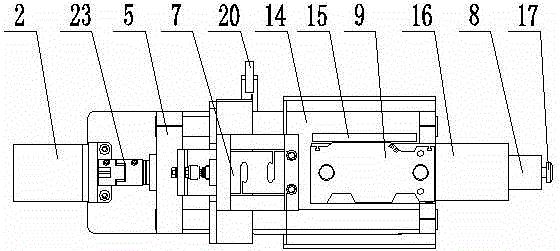

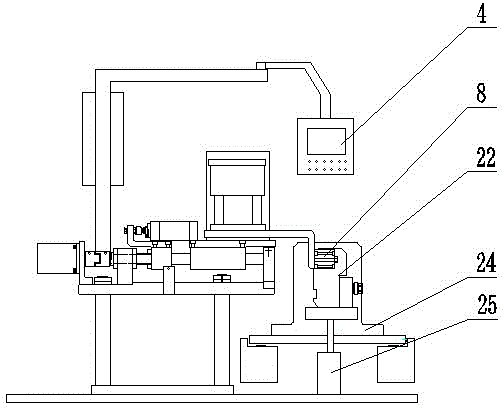

[0014] The sliding force detection device for pneumatic disc brakes consists of a frame 1, a servo motor 2, a program control cabinet 3, a control panel 4, a sliding seat 5, a sliding block 6, a sensor 7, a supporting cylinder 8 and a lifting cylinder 9. One side of the worktable of the frame 1 is equipped with a servo motor 2 through a motor mounting seat, and the worktable on one side of the servo motor 2 is equipped with a sliding rod 11 through a symmetrically installed support seat 10, and a sliding seat 5 is installed on the sliding rod 11 And sliding block 6, servo motor 2 is connected with sliding seat 5 through shaft coupling 23 and transmission screw mandrel 12.

[0015] The top of the sliding seat 5 is equipped with an L-shaped connecting plate 13, the top 6 of the sliding block is equipped with a mounting plate 14, and the lifting cylinder 9 is installed on the mounting plate 14 through the lifting cylinder mounting plate 15, and the lifting cylinder 9 is a double g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com