Double hydraulic cylinder synchronous control system and engineering machine applying control system

A synchronous control, dual hydraulic cylinder technology, applied in mechanical equipment, cranes, fluid pressure actuating devices, etc., can solve the problems of the difference in the back pressure of the left and right oil return, the high cost of system manufacturing, and the increased complexity of pipeline assembly. Improve the accuracy and eliminate the different effects of oil return back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

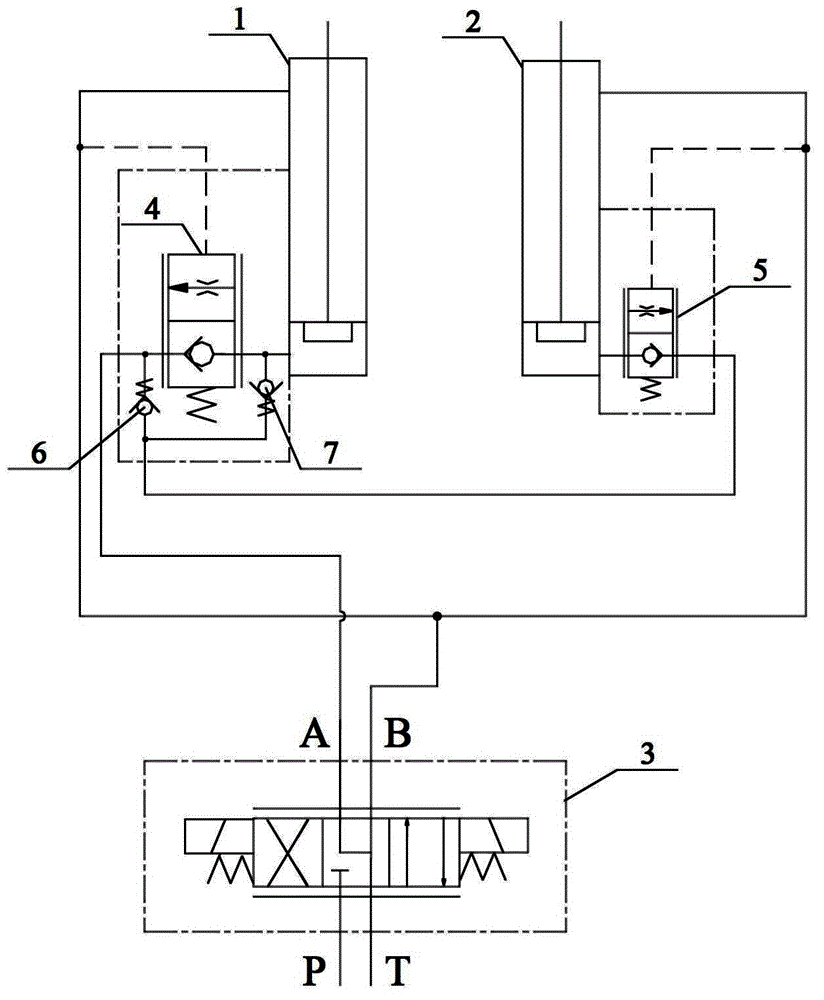

[0030] The core of the present invention is to provide a dual hydraulic cylinder synchronous control system, which can ensure the synchronism of the dual hydraulic cylinders and effectively control the manufacturing cost of the system through the optimization of component configuration. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0031] Without loss of generality, this implementation mode takes the jib luffing cylinder of the crane as the main body for detailed description. It should be understood that the jib luffing cylinder does not constitute a limit to the technical solution of this application, and the dual hydraulic cylinder synchronous control system can be applied to Any actuation system employing two hydraulic cylinders.

[0032] See image 3 , which is the working principle diagram of the double luffing cylinder synchronous control system described in this embodiment.

[0033] Same as the prior art, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com