Accompanying electroplating bar

A technology for accompanying strips and sheets, applied in the electrolysis process, electrolysis components, etc., can solve the problems of polluted copper tank, unadjustable length, easy to fall off, etc., to achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

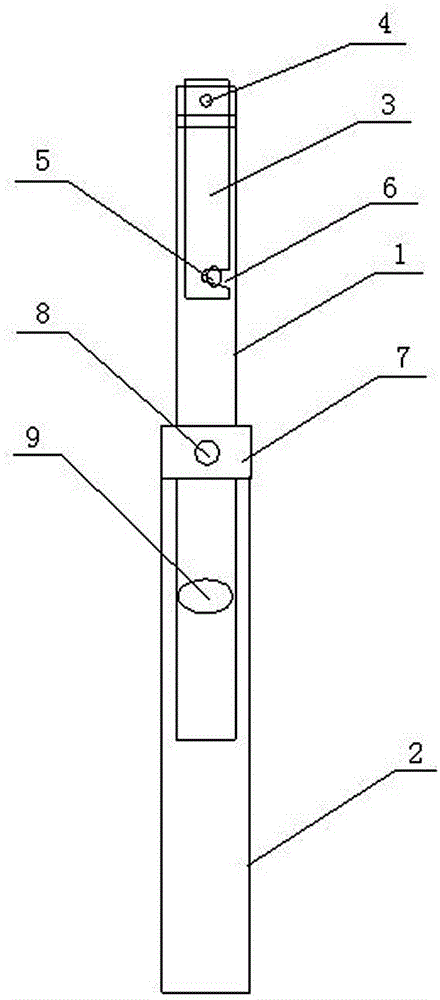

[0012] In order to further reveal the technical solutions of the present invention, the following describes the implementation of the present invention in detail in conjunction with the accompanying drawings: figure 1 As shown, the electroplating accompanying plating strip includes a base plating sheet 1 and an adjustable plating sheet 2 arranged below the base plating sheet 1, and the material of the base plating sheet 1 and the adjustable plating sheet 2 is stainless steel. The base plate 1 is movably connected with the adjustable plate 2, and the length of the accompanying plated strip can be automatically adjusted according to the length of different PCBs.

[0013] The upper end of the base plating sheet 1 is provided with a fixed plating sheet 3, the upper end of the fixed plating sheet 3 is movably connected with the base plating sheet 1 through a shaft 4, and the fixed plating sheet 3 can rotate around the shaft 4, thereby adjusting the fixed plating sheet. The angle be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com