High-efficiency environment-friendly grinding aid for wet grinding of phosphate ore

A technology of phosphate rock and grinding aids, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of increased grinding cost, difficult grinding of phosphate rock, and low grinding concentration, so as to reduce the grinding cost. Effects of cost, moisture reduction, and increased grinding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 40% caramel pigment, 20% potassium salt of acrylic acid and ethyl acrylate copolymer, 10% fulvic acid, 30% water, wherein the molar ratio of acrylic acid and ethyl acrylate copolymerization is 2:1, and the molecular weight of the copolymer is 5000. All components are mixed uniformly to obtain an efficient and environmentally friendly grinding aid for wet grinding of phosphate rock.

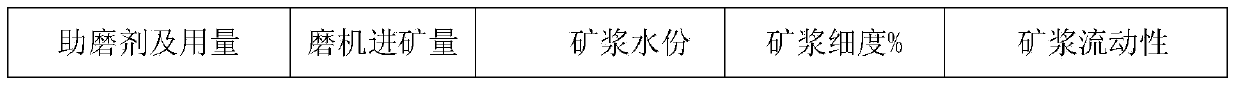

[0019] Comparison of the effects of using the above-mentioned high-efficiency and environmentally friendly grinding aids

[0020]

[0021]

Embodiment 2

[0023] 40% of caramel pigment, 20% of sodium salt of acrylic acid and ethyl acrylate copolymer, 20% of fulvic acid, 20% of water, wherein the molar ratio of acrylic acid and ethyl acrylate copolymerization is 2:1, and the molecular weight of the copolymer is 10000. All components are mixed uniformly to obtain an efficient and environmentally friendly grinding aid for wet grinding of phosphate rock.

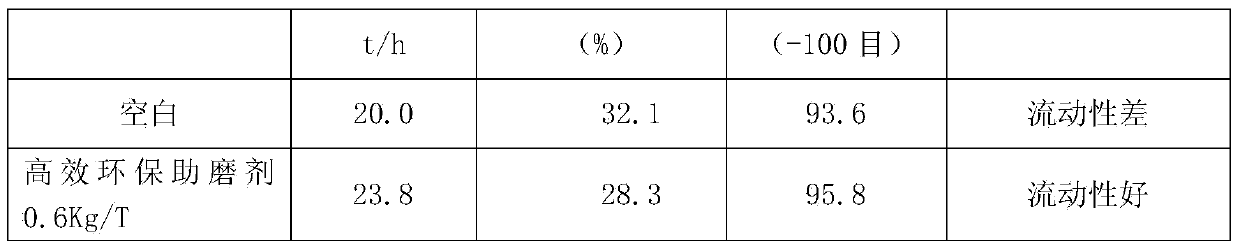

[0024] Comparison of the effects of using the above-mentioned efficient and environmentally friendly grinding aids:

[0025]

Embodiment 3

[0027] Caramel pigment 50%, sodium salt of acrylic acid and ethyl acrylate copolymer 10%, potassium salt of acrylic acid and ethyl acrylate copolymer 10%, fulvic acid 10%, water 20%, wherein the mole of acrylic acid and ethyl acrylate copolymer The ratio is 2:1, the molecular weight of the copolymer is 15,000, and the components are mixed uniformly to obtain an efficient and environmentally friendly grinding aid for wet grinding of phosphate rock.

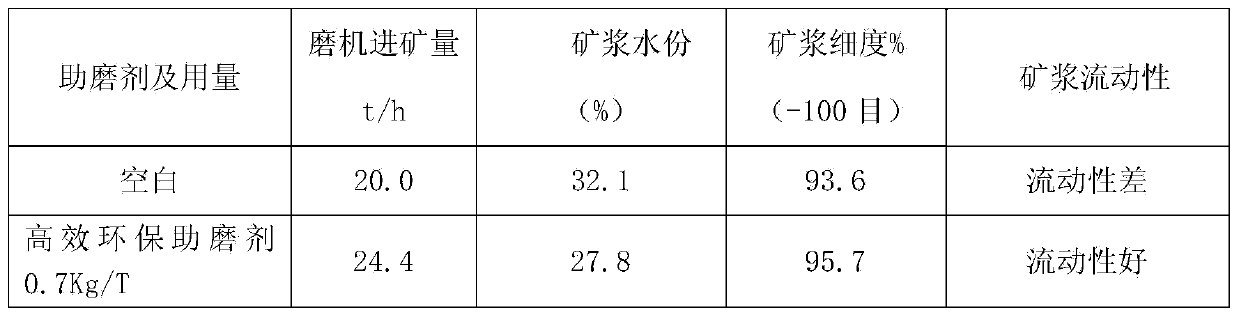

[0028] Comparison of the effects of using the above-mentioned efficient and environmentally friendly grinding aids:

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com