Noise-reduction tire pattern groove

A tire pattern and groove technology, applied in the direction of tire tread/tread pattern, tire parts, transportation and packaging, can solve the problems of noise, air pressure changes, air turbulence, etc., to reduce noise and air Can, eliminate the effect of air flow frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] refer to Figure 27 , Figure 28 , Figure 13 , the present invention is a special structural design aimed at the tread grooves of existing tires. As shown in the figure, the pattern groove 2 on the rubber tire body 1 includes longitudinal grooves and transverse grooves, and a convex-concave damping structure is provided in the groove wall 3 or the groove bottom 4 of the pattern groove 2 .

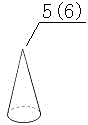

[0050]The convex-concave damping structure includes a convex point structure 5 , a concave point structure 6 , a convex rib structure 7 and a concave rib structure 8 .

[0051] Figure 1 to Figure 7 It is a schematic diagram of several structures of the bump-shaped structure 5 and the concave-point-shaped structure 6 of the present invention, including conical, columnar, square, and various combinations of cones and columns, and combinations of columns and columns. Figure 8 to Figure 11 It is a schematic diagram of several structures of the convex rib structure 7. The convex ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com