Cold expanding former

A technology of a former and a sleeve, which is applied in the field of pipeline connection, can solve the problems of high cost, poor welding stability, and easy falling off of copper rings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

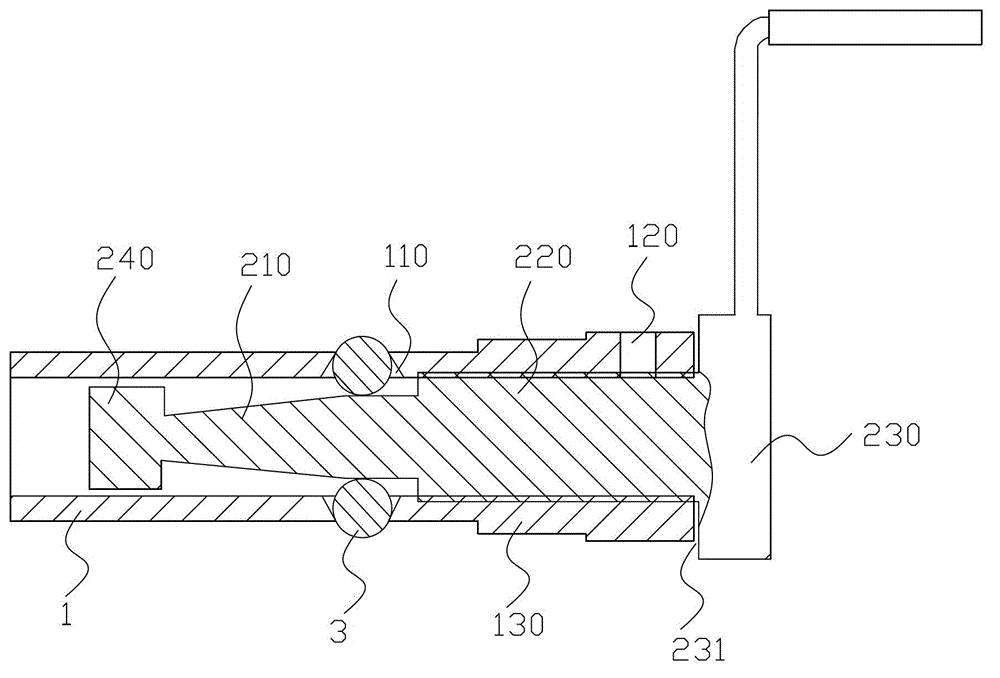

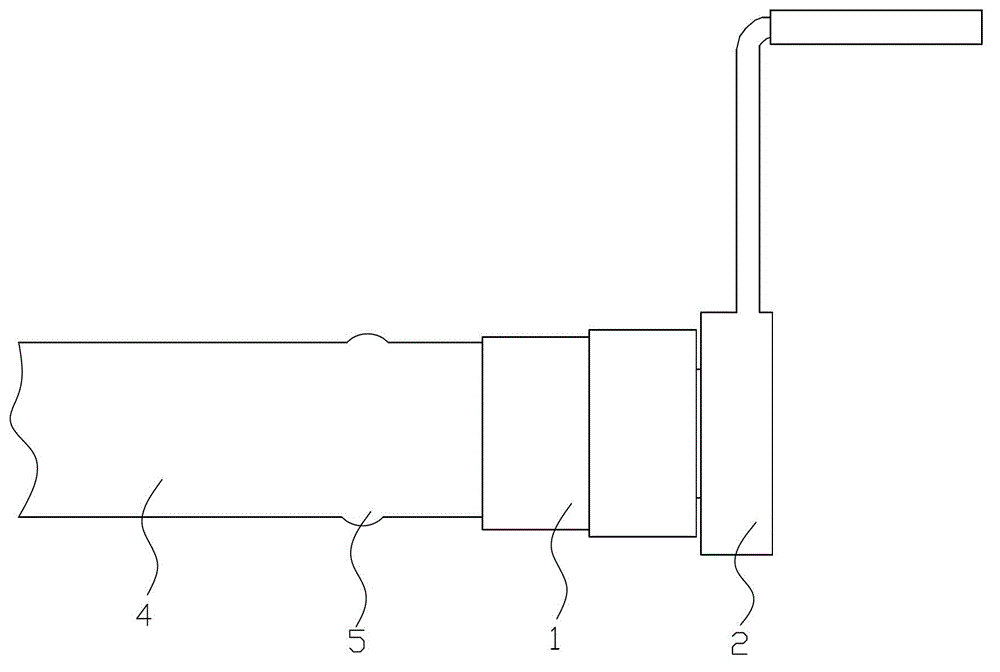

[0035] refer to figure 1 The difference between this embodiment and Embodiment 1 is that there are four balls 3 described in this embodiment, and there are four mounting holes 110, and the four mounting holes 110 are evenly spaced outside the same circumference of the sleeve 1. edge. Four balls are evenly arranged on the outer edge of the same circumference of the sleeve, so that the extruded heat pipe or other metal pipes are simultaneously squeezed by the four balls, and the forming speed of the protrusion is accelerated.

Embodiment 3

[0037] refer to figure 1 The difference between this embodiment and Embodiment 1 is that there are three balls 3 in this embodiment, and there are three mounting holes 110, and the three mounting holes 110 are evenly spaced in the same circumferential direction of the sleeve 1 on the outer edge. Three balls are evenly arranged on the outer edge of the same circumference of the sleeve, so that the extruded heat pipe or other metal tubes are simultaneously extruded by the three balls, and the forming speed of the protrusion is accelerated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com