Distiller

A technology for distiller and distillation chamber, which is applied in distillation separation, chemical instruments and methods, separation methods, etc., can solve problems such as increasing equipment cost, reducing efficiency, and difficulty in circulating distillation, and achieves accelerated work efficiency, convenient operation, and improved structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

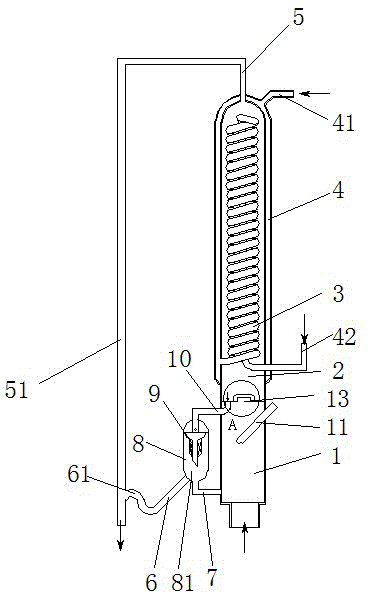

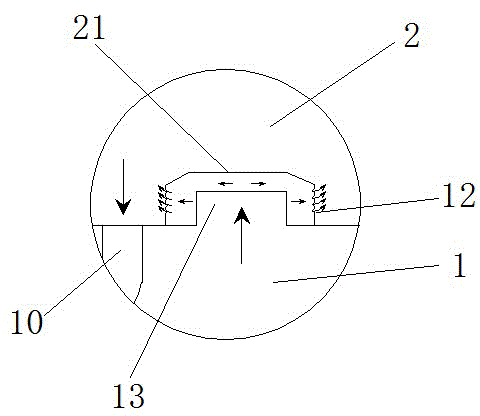

[0023] Example 1, such as figure 1 As shown, a distiller, all materials are made of quartz, including a collection chamber 1 for collecting gas, the upper part of the collection chamber 1 communicates with the distillation chamber 2 through a communication port 13, and the collection chamber 1 and the distillation chamber 2 are All in one connection. A temperature measuring tube 11 is integrally connected to the collecting chamber 1 , and one end of the temperature measuring tube 11 is opened, and the opening direction faces outside the collecting chamber 1 . In this way, the user can measure the temperature inside the still outside. The top of the distillation chamber 2 is communicated with a pressure relief pipe 5 . The spiral tube 3 for condensing gas is arranged in the distillation chamber 2, and the spiral tube 3 communicates with the water storage chamber 4 arranged on the periphery of the distillation chamber 2, and the water storage chamber 4 is also integrally conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com