A wafer transfer device for multi-chamber processing

A technology for transferring devices and wafers, applied in transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as cross-contamination, improve efficiency, reduce cross-contamination, and avoid being twisted and broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

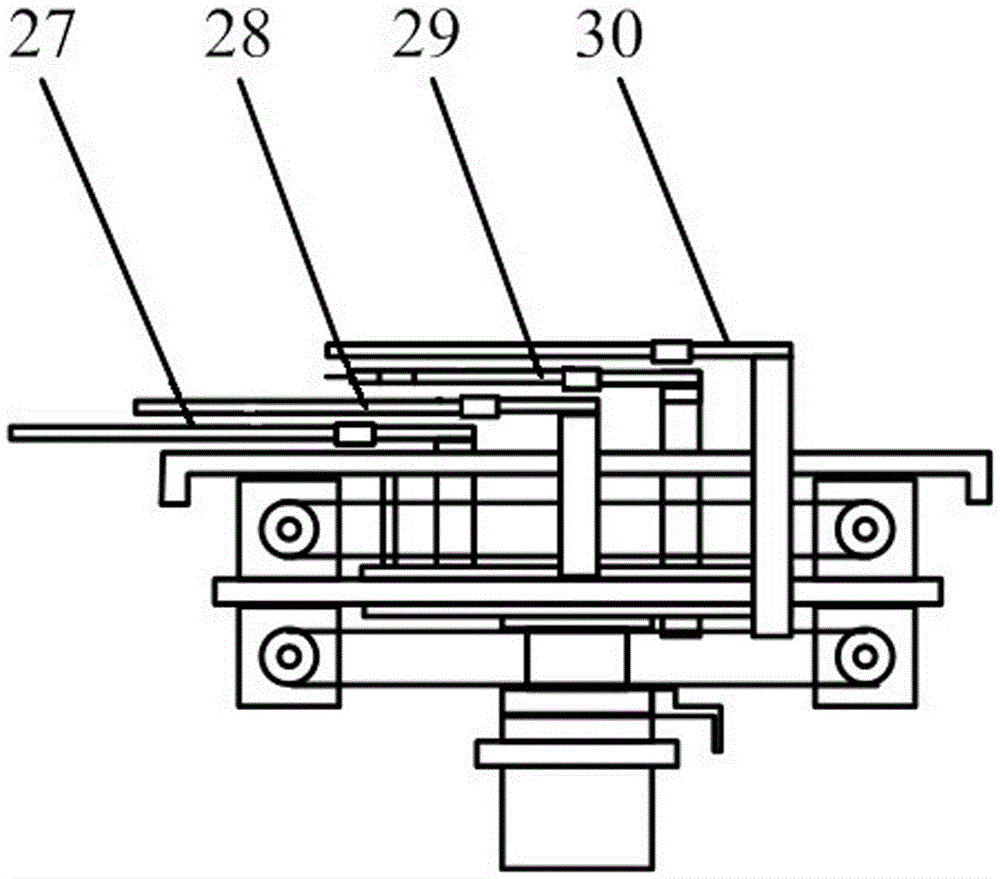

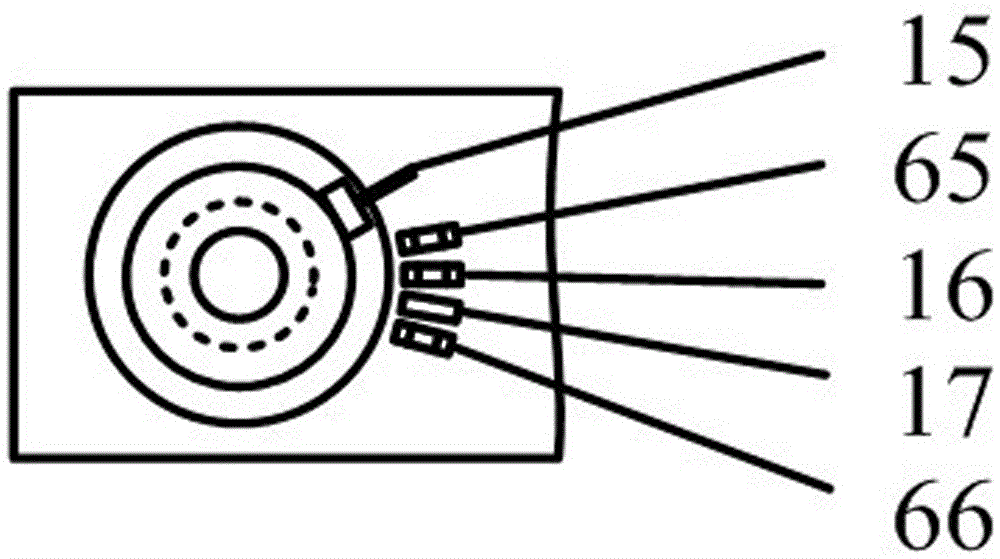

[0035] Such as Figure 1-8As shown, the wafer transfer device mainly includes a lifting motor 2, a lead screw 4, a lifting platform 13, a rotating motor 18, a rotating platform 23, at least three mechanical grippers, and the same number of mechanical grippers for driving the mechanical grippers. The driving mechanism; wherein, the output end of the lifting motor 2 is connected with the screw 4 through the coupling 3, the lifting platform 13 is installed on the screw 4 and the guide rail Z7, and the lifting motor 2 rotates to drive the lifting platform 13 to move up and down; the rotating motor The stator of 18 is installed on the lifting platform 13, and the rotary platform 23 is installed on the rotor of the rotary motor 18, and the rotary platform 23 is driven to rotate when the rotary motor 18 rotates. connected; the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com