Display device, method of manufacturing the same, and electronic device

A technology for display devices and display parts, applied in tube/lamp screen manufacturing, optics, instruments, etc., can solve problems such as insufficient prevention of external light reflections, and achieve the effects of preventing charging, suppressing brightening, and suppressing reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 5 example

[0032]

[0033]

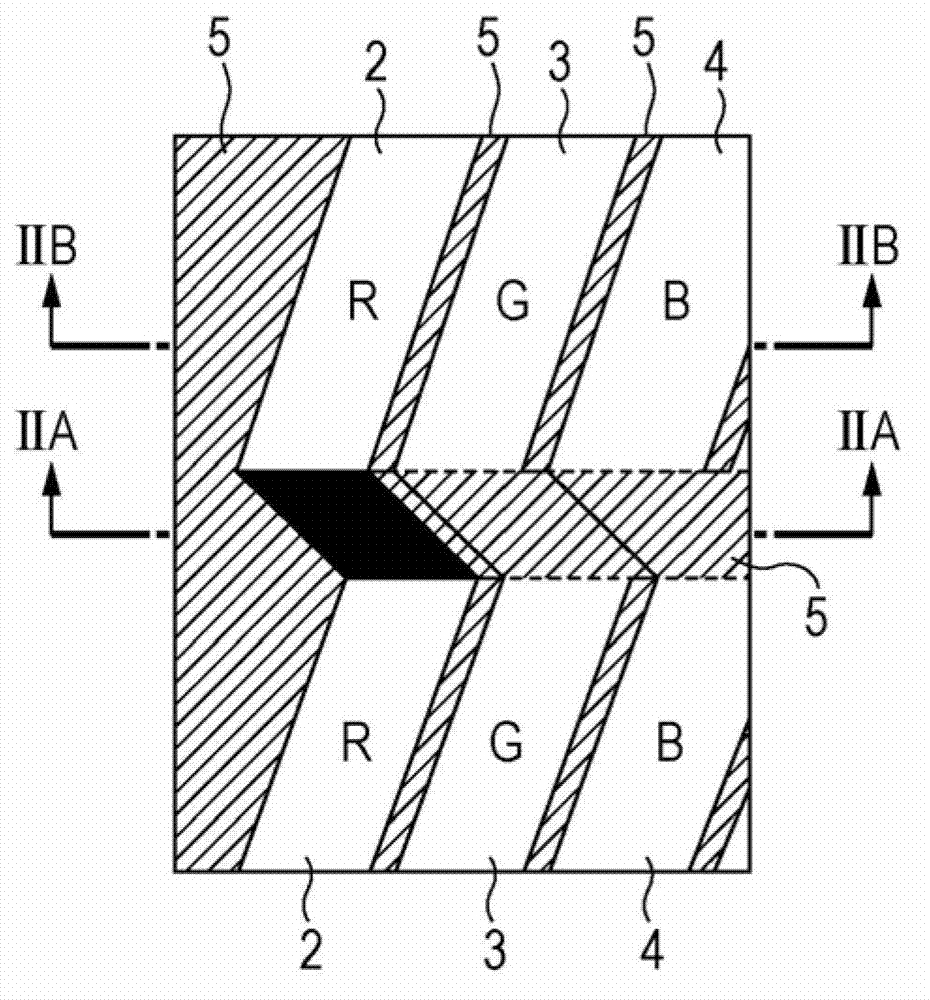

[0034] A liquid crystal display device will be described as an example of the display device according to the embodiment. First, refer to Figure 8 A schematic configuration of the liquid crystal panel 30 is described.

[0035] Figure 8 is a schematic diagram showing a schematic configuration example of a cross-sectional structure of the liquid crystal panel 30 .

[0036] Such as Figure 8 As shown, the liquid crystal panel 30 includes a pixel substrate and an opposite substrate. The pixel substrate includes a thin film transistor (TFT) substrate 31 used as a circuit board, a pixel electrode 32 and a polarizer 37. The opposite substrate is set to face the pixel substrate and includes glass A substrate 34 , a color filter 33 , a driving electrode COML and a polarizer 35 . The liquid crystal panel 30 includes a liquid crystal layer 36 arranged to be interposed between a pixel substrate and an opposite substrate.

[0037] The pixel substrate includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com