Independent internal furnace type water-cooled furnace

A water-cooled furnace and furnace technology, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems that have not yet been found to have independent furnace water-cooled furnaces, and achieve safe sealing, simple structure, and tightness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. It should be noted that this embodiment is illustrative, not restrictive, and cannot limit the protection scope of the present invention.

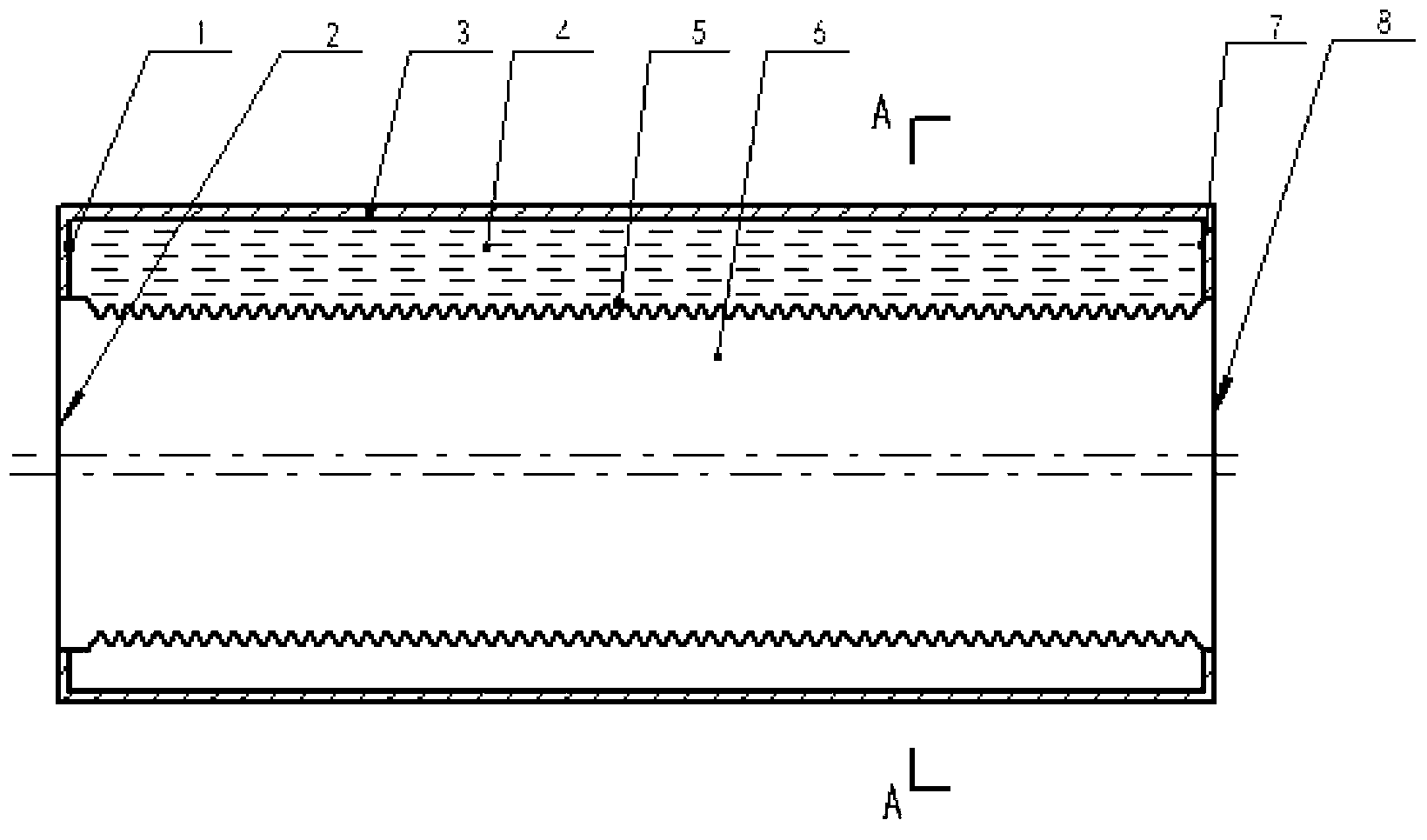

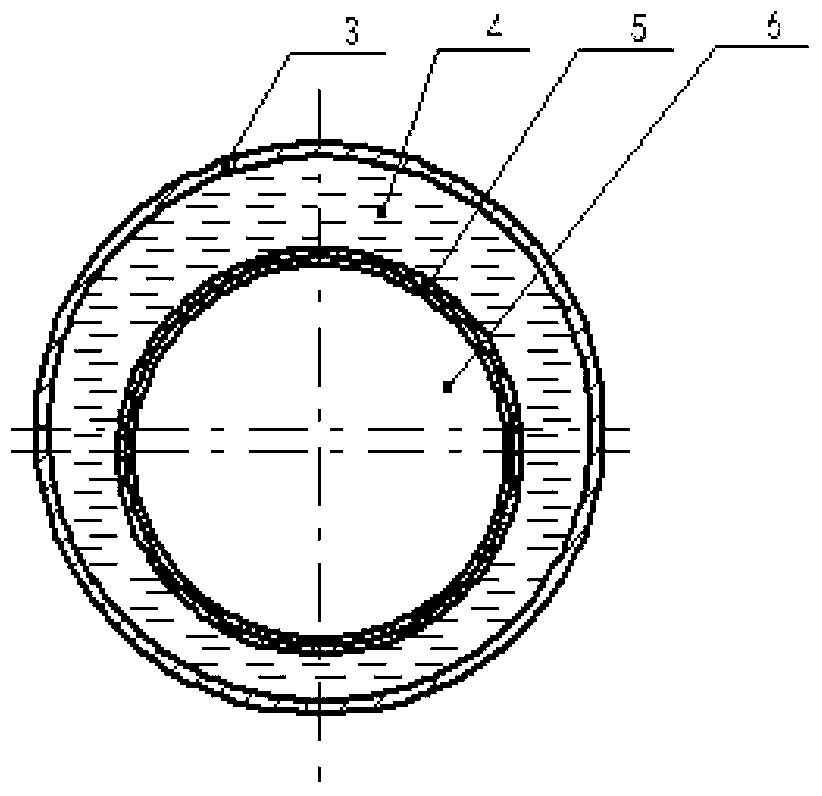

[0015] An independent furnace-type water-cooled furnace, including a pot shell body 3, a furnace body body 5, a front tube plate 1, a rear tube plate 7, a burner interface 2 and a smoke outlet 8, and furnaces are installed at intervals in the pot shell body The front end and the rear end of the cylinder body, the pot shell cylinder body and the furnace cylinder body are packaged with the front tube sheet and the rear tube sheet respectively, and the interlayer formed after the packaging contains the working fluid 4, which can be water or Heat conduction oil; a burner interface is provided at the front end of the furnace cylinder, which is used to install the burner, and the rear end of the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com