Threaded sliding sleeve with ball seat capable of being taken out

A threaded and ball-seat technology, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of inconvenient tools and inability to discharge pipe string parts, and achieve the effect of not easy to fall off and safe and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

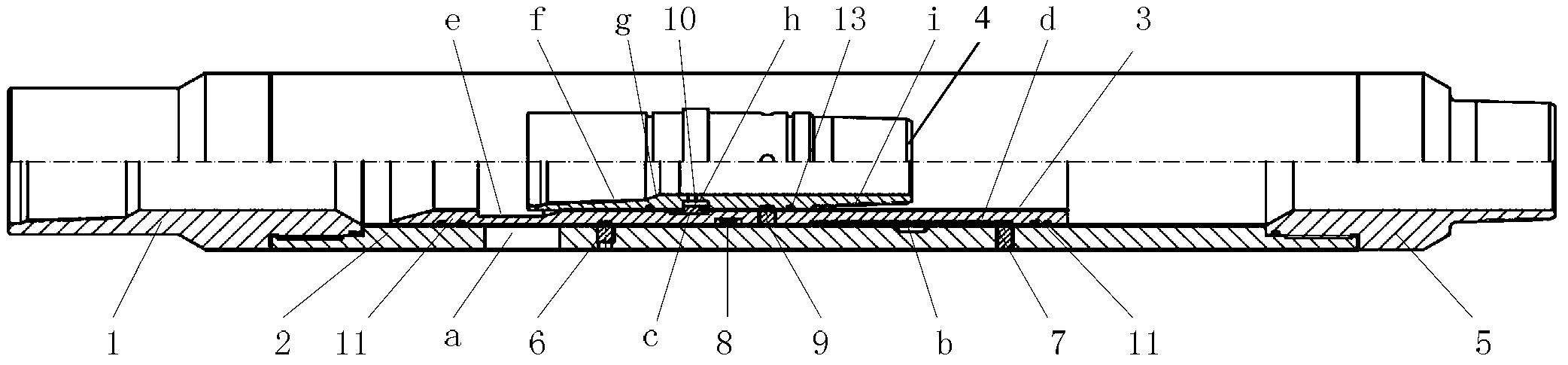

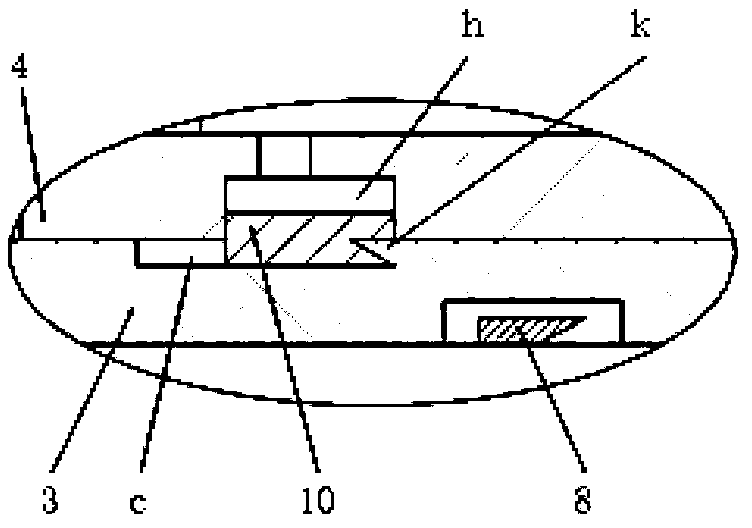

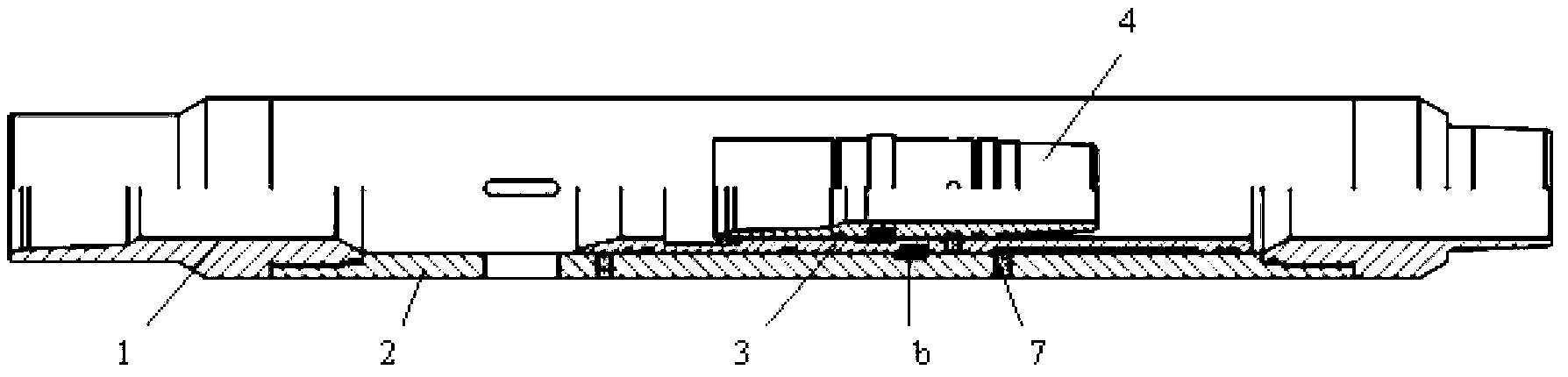

[0015] The structure of the one-pass thread type removable ball seat sliding sleeve of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] see figure 1 with figure 2 The one-pass threaded ball seat sliding sleeve of the present invention includes a sliding sleeve body composed of an upper joint 1, an outer cylinder 2 and a lower joint 5 which are threaded in sequence, an inner sliding sleeve 3 installed in the outer cylinder 2 and The ball seat cylinder 4 arranged in the inner sliding sleeve 3, the sliding sleeve body and the inner sliding sleeve 3 are fixed by the shear nails 6, the inner sliding sleeve 3 and the ball seat cylinder are fixed by the shear nails 9, the inner sliding sleeve Seal rings 11 are used to seal between the two ends and the body of the sliding sleeve.

[0017] A liquid outlet hole a is arranged on the upper part of the outer cylinder 2, and a spring hole b is arranged on the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com