Internal flush water-proof expansion-end-proof drill pipe

A drill pipe and female head technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of increasing the production cost of the enterprise, the drill bit cannot be cooled, and the end face of the drill pipe is swollen, so as to improve production efficiency, low processing cost, Avoid the effect of drill pipe swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

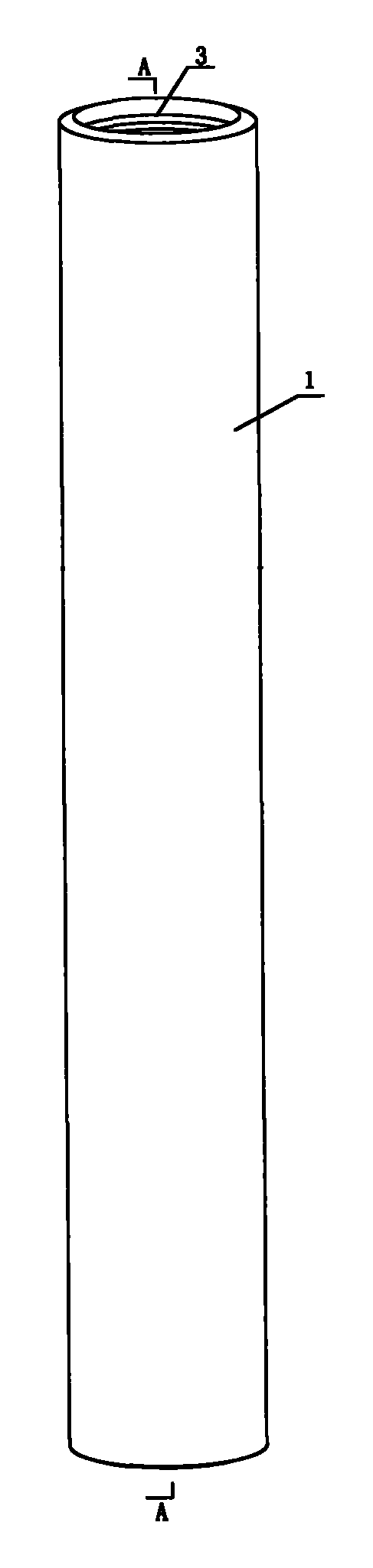

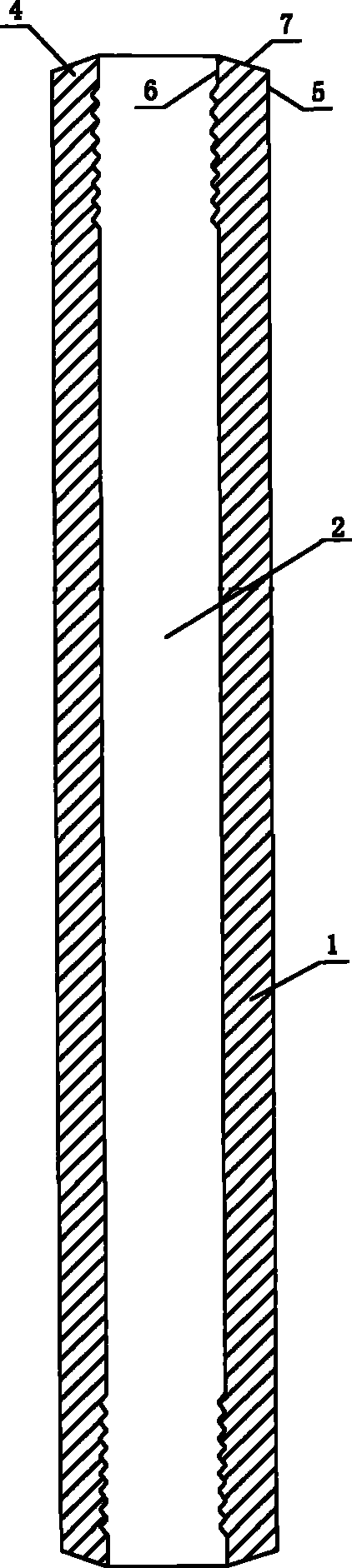

[0011] Such as figure 1 , figure 2 As shown, the inner flat buckle waterproof anti-swelling head drill pipe of this embodiment includes a drill pipe body 1, a female head 3 at both ends of the drill pipe body and a central axis channel 2 of the drill pipe body, and the outer ends of the female head 3 at both ends of the drill pipe body 1 are provided with waterproof The protrusion 4, the outer wall 5 of the waterproof protrusion is parallel to the inner wall 6 of the waterproof protrusion, and the angle between the end wall 7 of the waterproof protrusion and the central axis channel 2 of the drill pipe body is 60°. The inner flat buckle waterproof and anti-swollen head drill pipe processed in this way can prevent water from leaking at the threaded connection between the drill pipe female head 3 and the drill pipe joint, and can effectively prevent water leakage when cooperating with the waterproof groove on the drill pipe joint. The drill pipe body 1 is subjected to a large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com