Extracting process of swainsonine in astragalus strictus

A technology of swainsonine and extraction process, which is applied in the direction of organic chemistry, can solve the problems of long extraction time, impact on cavitation, long time, etc., and achieve the effect of clear extraction liquid, increased cost, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

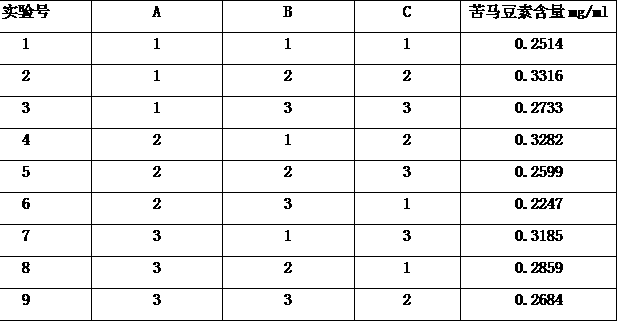

Method used

Image

Examples

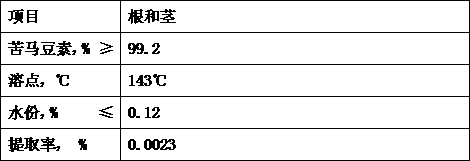

Embodiment 1

[0060] A process for extracting swainsonine from straight stem astragalus includes the following process steps:

[0061] a. Take the roots and stems of straight stem Astragalus as raw materials, directly pulverize and pass through a 70-mesh sieve, add petroleum ether to the pulverized raw materials to form a solution, and the weight-volume ratio of raw materials to petroleum ether is 1:30g / ml;

[0062] b. After 3 hours, perform ultrasonic degreasing on the solution to recover petroleum ether. The ultrasonic degreasing frequency is 55KHz, the temperature is 20℃, and the time is 15min;

[0063] c. Control the moisture content of the raw materials after ultrasonic degreasing to 30%;

[0064] d. Use 85% methanol as the solvent, and after soaking for 0.5 hours at a microwave output of 650W, perform microwave extraction for 35 seconds to obtain an extract. The weight-volume ratio of raw material to methanol is 1:45g / ml;

[0065] e. Evaporate the extract at 130°C under normal pressure for 25mi...

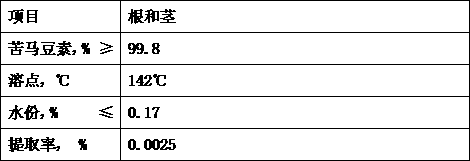

Embodiment 2

[0070] A process for extracting swainsonine from straight stem astragalus includes the following process steps:

[0071] a. Take the roots and stems of straight-stem Astragalus as raw materials, directly pulverize and pass through an 80-mesh sieve, add petroleum ether to the pulverized raw materials to form a solution, and the weight-volume ratio of the raw materials to the petroleum ether is 1:40g / ml;

[0072] b. After 5 hours, ultrasonically degrease the solution to recover petroleum ether. The frequency of ultrasonic degreasing is 60KHz, the temperature is 25°C, and the time is 25min;

[0073] c. Control the moisture content of the raw materials after ultrasonic degreasing to 70%;

[0074] d. Use 90% methanol as the solvent again, and after soaking for 1 hour at a microwave output of 700W, perform microwave extraction for 40s to obtain an extract. The weight-volume ratio of raw material to methanol is 50g / ml;

[0075] e. Evaporate the extract at 140°C under normal pressure for 30 min...

Embodiment 3

[0080] A process for extracting swainsonine from straight stem astragalus includes the following process steps:

[0081] a. Take the roots or stems of Astragalus straight-stemmed as raw materials, pulverize directly and pass through a 75-mesh sieve, add petroleum ether to the pulverized raw materials to form a solution, and the weight-volume ratio of the raw materials to the petroleum ether is 1:35g / ml;

[0082] b. After 4 hours, perform ultrasonic degreasing on the solution to recover petroleum ether. The ultrasonic degreasing frequency is 57KHz, the temperature is 23°C, and the time is 20min;

[0083] c. Control the moisture content of the raw materials after ultrasonic degreasing to 65%;

[0084] d. Use 87% methanol as the solvent. After soaking for 0.8 hours, the microwave output power is 680W, and the microwave extraction is performed for 37 seconds to obtain the extract. The weight-volume ratio of raw material to methanol is 1:48g / ml;

[0085] e. Evaporate the extract at 135°C und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com