Storage equipment used in alumina industry

A technology for storage equipment and alumina, which is applied in the direction of containers, packaging, transportation and packaging, etc. It can solve the problems of the impeller of the easily damaged discharge pump and the wear of the bottom plate of the storage equipment, so as to ensure safe use and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

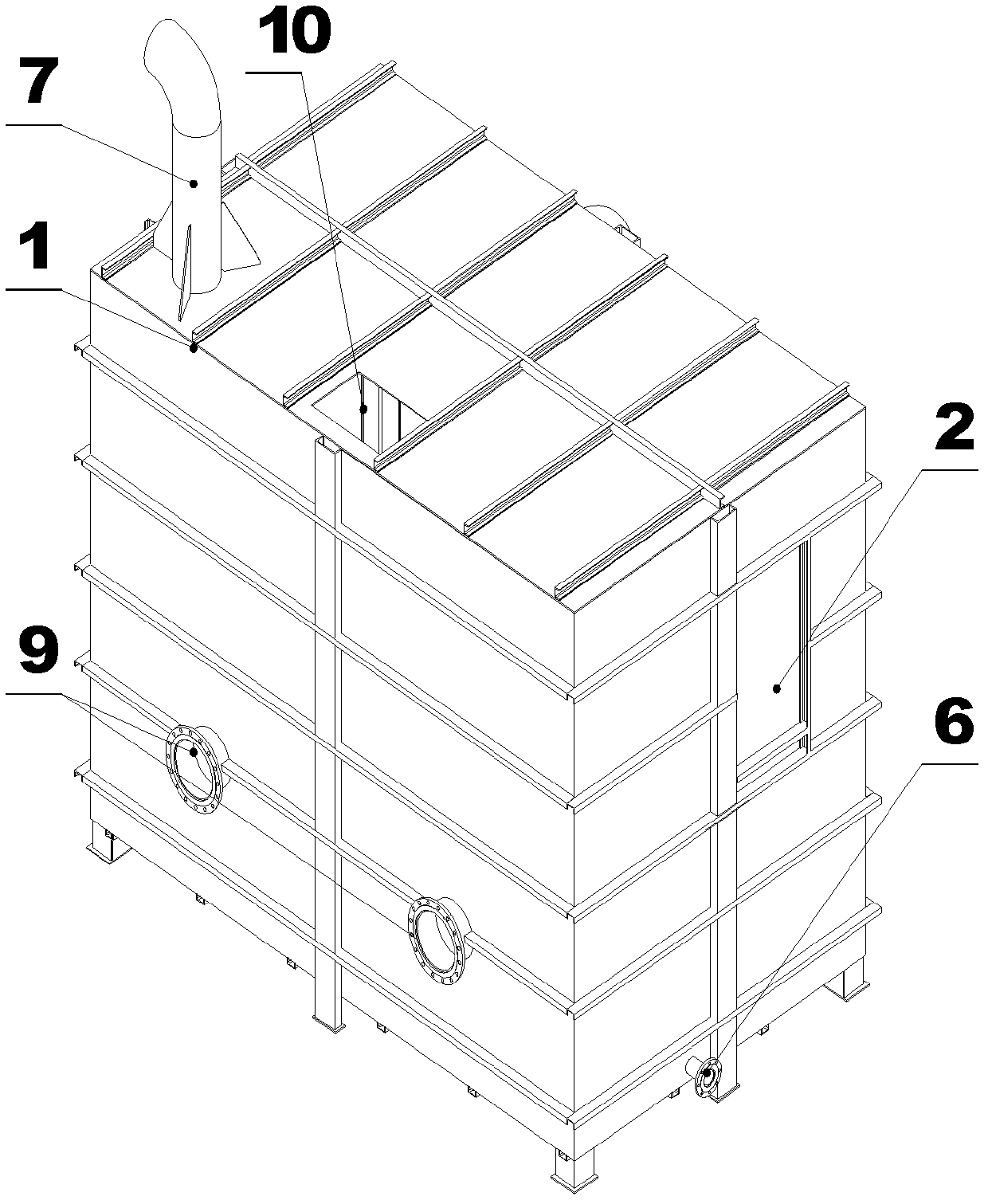

[0023] Such as Figure 1-2 As shown, the slurry storage equipment of the present invention mainly includes: tank body 1, feed inlet 2, material guide chute 3, anti-shock cone 4, bottom angle inclined plate 5, discharge port 6, vent hole 7, overflow Port 8, discharge port 9, observation hole 10 and grid screen 11, etc., the specific structure is as follows:

[0024] The tank body 1 of the storage equipment is fixed on the foundation; the feed port 2 is set on the middle and upper part of the side of the tank body 1. If the feed port 2 is double-opened, it needs to be opened symmetrically, and the slurry can form convection to avoid local accumulation and scarring; The material guide chute 3 in the tank body 1 is horizontally inclined downward to have a certain slope (10-80°),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com