Protective type four-way wooden pallet

A protective, wooden technology, applied in rigid containers, containers, packaging, etc., can solve the problems of high cost, high wood consumption, unfavorable environmental protection, etc., and achieve the effect of reducing usage, reducing manufacturing cost, and reducing damage ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, structure of the present invention is described in further detail:

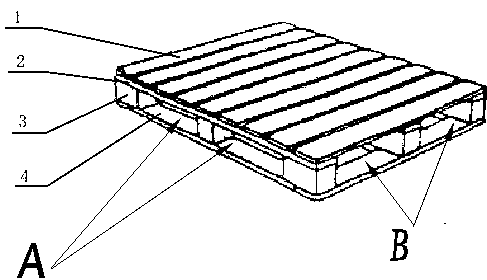

[0011] Such as image 3 As shown, a protective four-way entry wooden pallet includes an upper panel 1, a middle panel 2, a wooden support 3, a lower panel 4 and a steel strip protection groove 5, and five upper panels 1 and three middle panels 2 Nail each other vertically, and then place nine wooden stays 3 in the middle and both ends of each middle panel 2 respectively, then nail the wooden stays 3 to the middle panel 2 one by one, and finally, connect the lower panel 4 to the The wooden stays 3 are nailed together, and the nailing direction is consistent with the direction of the upper panel 1, wherein, the nailed surface of the upper panel 1 and the middle panel 2 located between two adjacent lower panels 4 is processed into a straight grooved steel Band protection groove 5, the width and depth dimension of groove can place the used steel band and get...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com