Tool constant velocity device

A technology of constant velocity device and cutting tool, applied in the direction of driving device, manufacturing tool, metal processing mechanical parts, etc., can solve the problems of difficult to guarantee machining accuracy, complex transmission error of transmission mechanism, etc., to eliminate low-frequency vibration, less transmission error, motion smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

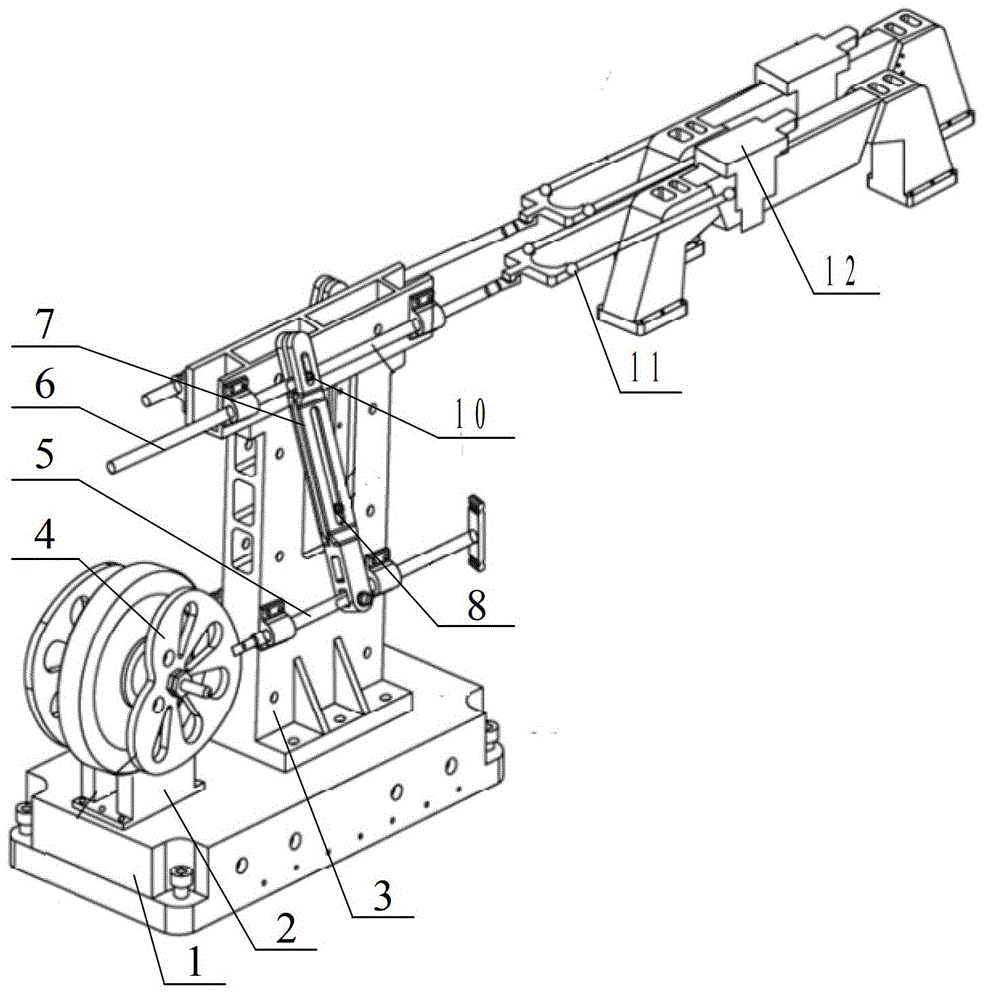

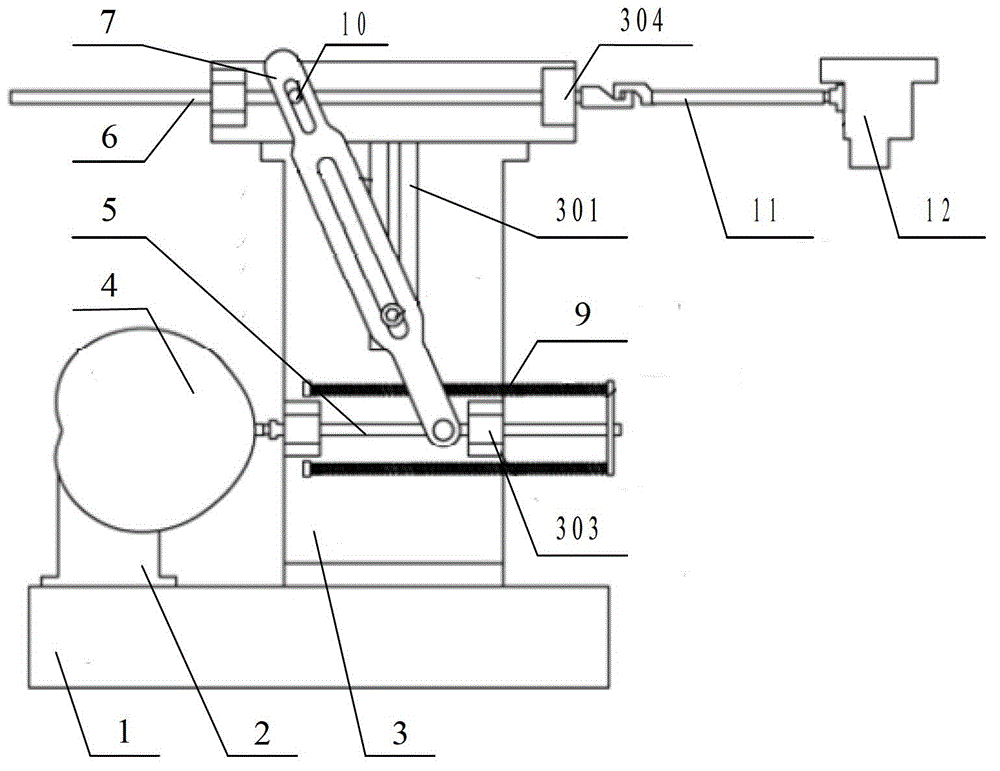

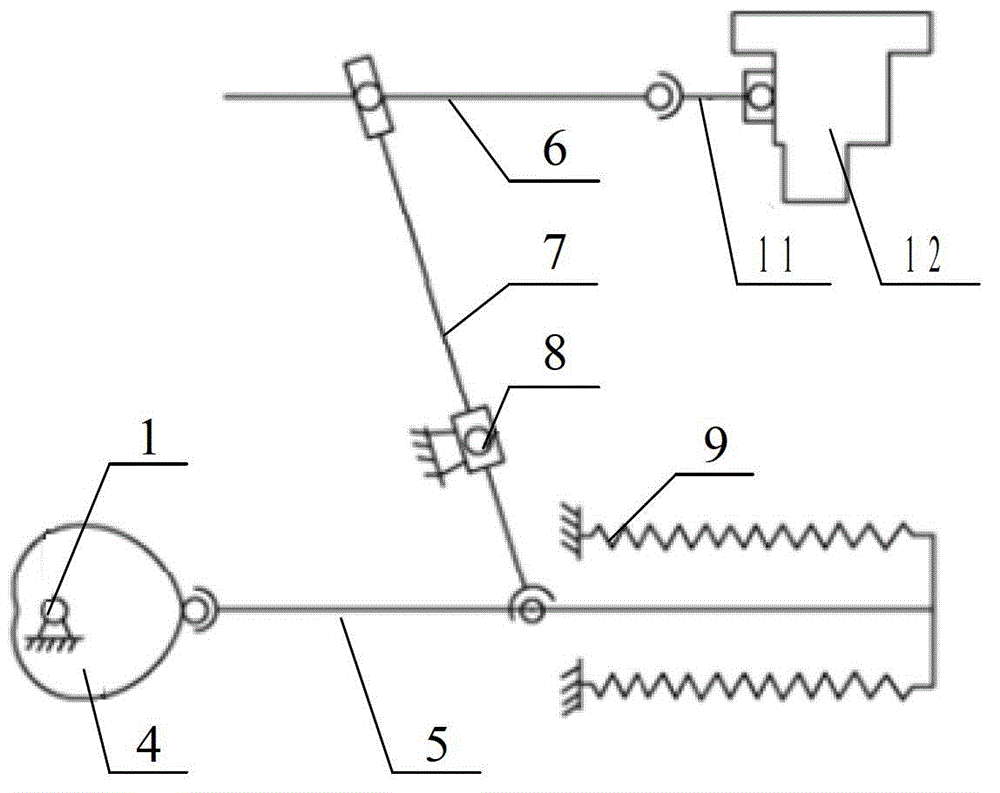

[0022] See attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 , The tool constant velocity device of the present invention comprises two sets of tool constant velocity mechanisms, a base 1, a first mounting frame 2 and a second mounting frame 3; the tool constant velocity mechanism comprises a constant velocity cam 4, a first push rod 5, The second push rod 6, the swing rod 7 and the adjustment knob 8; the first push rod 5 is connected with the constant velocity cam 4, and can reciprocate under the drive of the constant velocity cam 4, and the swing rod 7 One end is connected to the first push rod 5, and the other end is connected to the second push rod 6. There is a chute A705 in the middle of the swing rod 7, and a T-shaped mounting groove is provided on the second mounting frame 3. The mounting seat 301 of 302 is provided with two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com