Multilevel particle filter used in MOCVD device

A particle filter and equipment technology, applied in the field of multi-stage particle filters, can solve problems such as inferior deposition, damage, vacuum pump blockage, etc., and achieve the effects of convenient disassembly, good filtering effect and safe cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creation features, achievement goals and effects of the present invention easy to understand and understand, the present invention will be further described below with reference to the specific drawings.

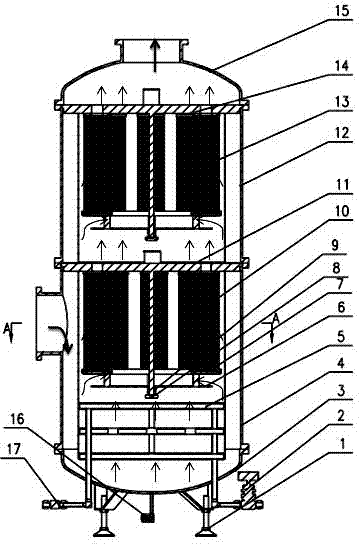

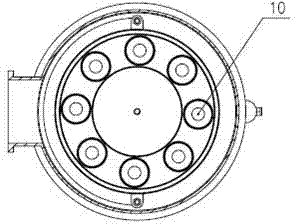

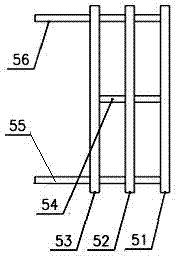

[0029] like figure 1 As shown, the tank body of the dual-stage particle filter of the present invention is composed of four parts: a bottom cover 3 , a front-stage tank body 4 , a rear-stage tank body 12 and an upper cover 15 . The air inlet is arranged on the side of the front-stage tank body 4 , and the air outlet is arranged on the top of the upper cover 15 . The four parts of the tank are connected and sealed by flanges with sealing grooves to ensure that the gas in the tank does not leak. Three support frames are welded on the bottom cover 3, and three feet 1 are installed on the support frames, which play the role of supporting the entire tank body.

[0030] A water cooling plate system 5 is arranged on the arc surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com