Low-pass filter based on helical metal wire

A low-pass filter and metal wire technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of limited stop-band suppression depth, low power capacity, and inability to fine-tune, and achieve high pass-band cut-off frequency, debugging The effect of convenience and simple structure processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

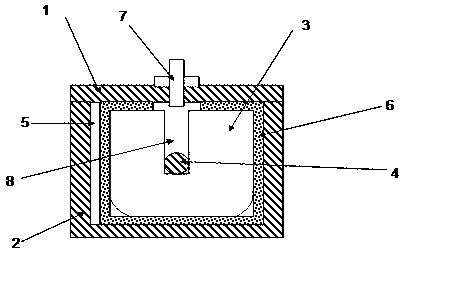

[0035] Such as figure 1 , figure 2 As shown, a low-pass filter based on a spiral metal wire, including a base 2 provided with a metal cavity 5, and a cover plate 1 arranged on the base 2, also includes a metal wire 4 and an insulating material 6, and is located on the metal At least three metal plates 3 in the cavity 5 are characterized in that the metal plates 3 are connected together by a metal wire 4, and the metal plates 3 are insulated from the metal cavity 5 by an insulating material 6; The cross-sectional shape is rectangular. The metal wire 4 is a column, and its cross-sectional shape is consistent along its axis; the metal wire 4 is in a spiral shape between two adjacent metal plates 3 .

[0036] The cross-sectional shape of the metal wire 4 is circular. The cross-sectional shape of the metal wire 4 is a rectangle. The cross-sectional shape of the metal plate 3 perpendicular to the axis of the metal wire 4 is rectangular, and the surface of the metal plate 3 para...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com