Charging resistor for aluminum-alloy wind power plant

A technology for charging resistors and wind farms, which is applied to resistors, resistor components, resistor installation/support, etc., and can solve problems such as large inductance, high temperature, and low resistance accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

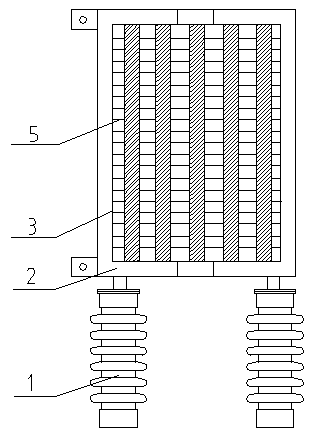

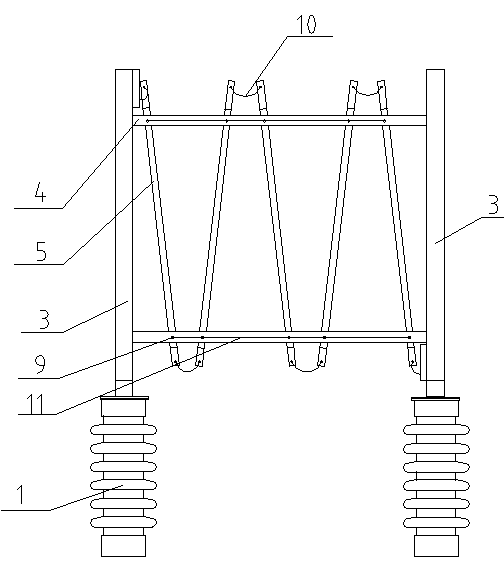

[0012] like figure 1 As shown in -3, the present invention includes a support insulator base 1, a frame 2 is arranged on the support insulator base 1, and the frame 2 includes a square aluminum alloy frame body 3 arranged symmetrically on both sides and arranged between the aluminum alloy frame bodies 3 on both sides. Insulating crossbeams 4 between them, a number of resistance units 5 are fixed inside the frame 2.

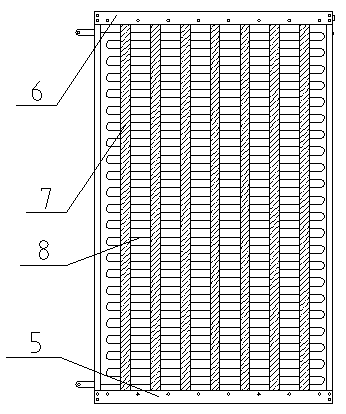

[0013] The resistance unit 5 includes a square frame body 6, and several vertically arranged non-alkali untwisted glass filaments 7 are evenly arranged in the square frame body 6, and a resistance wire 8 is wound on the non-alkali non-twisted glass filament 7, and the resistance unit 5 is fixed by a fixed bolt. 9 is fixed on the insulating beam 4 of the frame, and the resistance units 5 are connected in sequence through wires 10 .

[0014] There are gaps between the resistance units 5 , and the resistance units 5 are installed on the frame 2 in an M shape.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com