A remote operation control system of a crane for delayed coking

A control system and remote operation technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as environmental pollution, on-site operator injury, etc., to avoid pollution damage, reduce pollution, and run control precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

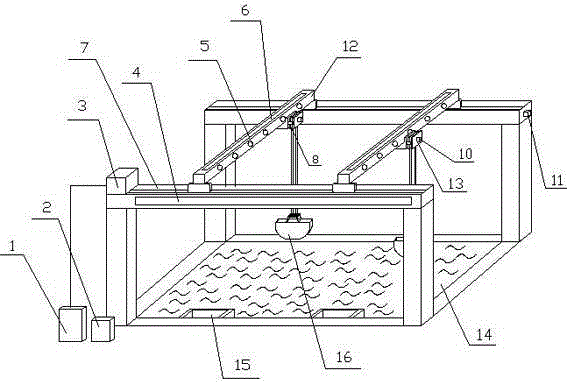

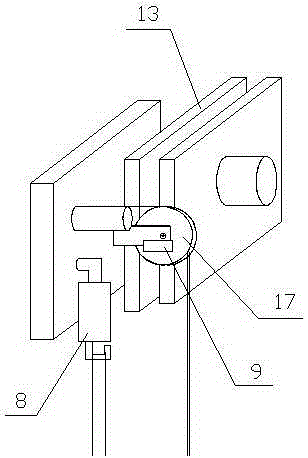

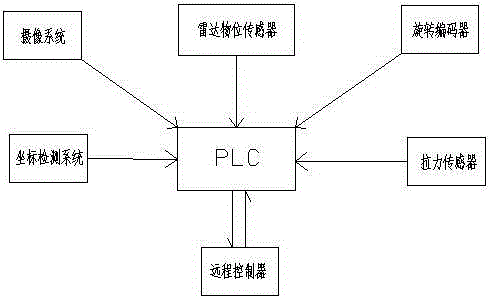

[0023] The specific embodiments of the present invention are described below in conjunction with the drawings: figure 1 , figure 2 As shown, a remote operation control system for a crane for delayed coking includes a PLC, a junction box 3, a coordinate detection system, a camera system, a radar level sensor 5, a tension sensor 8 and a rotary encoder 9. The PLC is equipped with a remote Controller interface, used to connect to remote controller 2. The coordinate detection system includes displacement detection sensor II 6 and displacement detection sensor I 4, displacement detection sensor II 6 is fixed on the cart along the length of cart 12, and displacement detection sensor I 4 is along the length of truss 7 The direction is fixed on the truss, the rotary encoder 9 is set on the pulley block 17 of the trolley, the vertical displacement of the grab is calculated by checking the rotation of the pulley, and the displacement detection sensor II 6 and the displacement detection sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com