Remote operation control system of overhead traveling crane for delayed coking

A control system and remote operation technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as environmental pollution, on-site operator injury, etc., to avoid pollution damage, reduce pollution, and run control precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

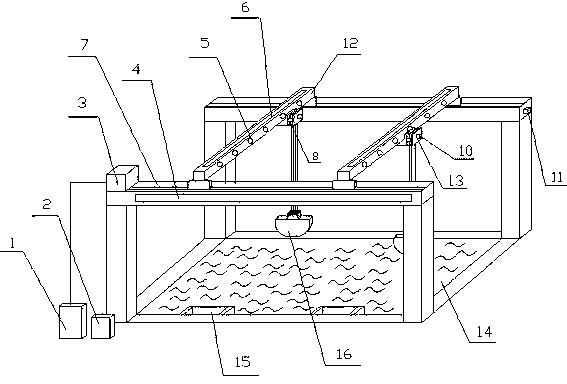

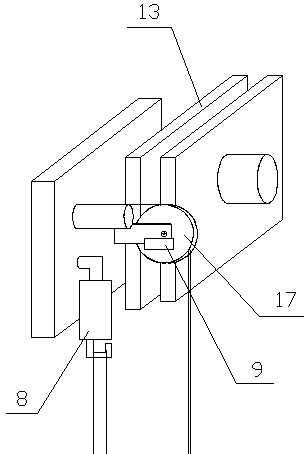

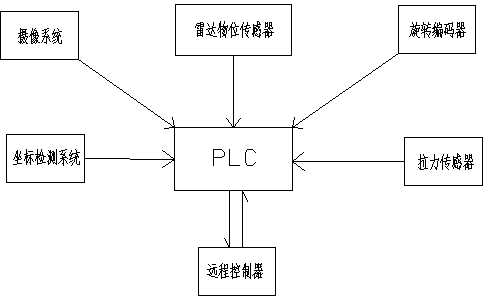

[0023] The specific embodiment of the present invention is described below in conjunction with accompanying drawing: as figure 1 , figure 2 As shown, a remote operation control system for a crane for delayed coking, including a PLC, a junction box 3, a coordinate detection system, a camera system, a radar level sensor 5, a tension sensor 8 and a rotary encoder 9, and a remote The controller interface is used to connect the remote controller 2. The coordinate detection system includes displacement detection sensor II6 and displacement detection sensor I4. The displacement detection sensor II6 is fixed on the cart along the length direction of the cart 12, and the displacement detection sensor I4 is along the length of the truss 7. The direction is fixed on the truss, and the rotary encoder 9 is set on the pulley block 17 of the trolley. The vertical displacement of the grab is calculated by checking the rotation of the pulley, and the displacement detection sensor Ⅱ6 and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com