Electrode structure applied to dielectric liquid lens

A technology of electrode structure and substructure, applied in lens, optics, instrument, etc., can solve the problems of long displacement distance, long reaction time of dielectric liquid lens, slow deformation of liquid droplets, etc. The effect of increasing and decreasing reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

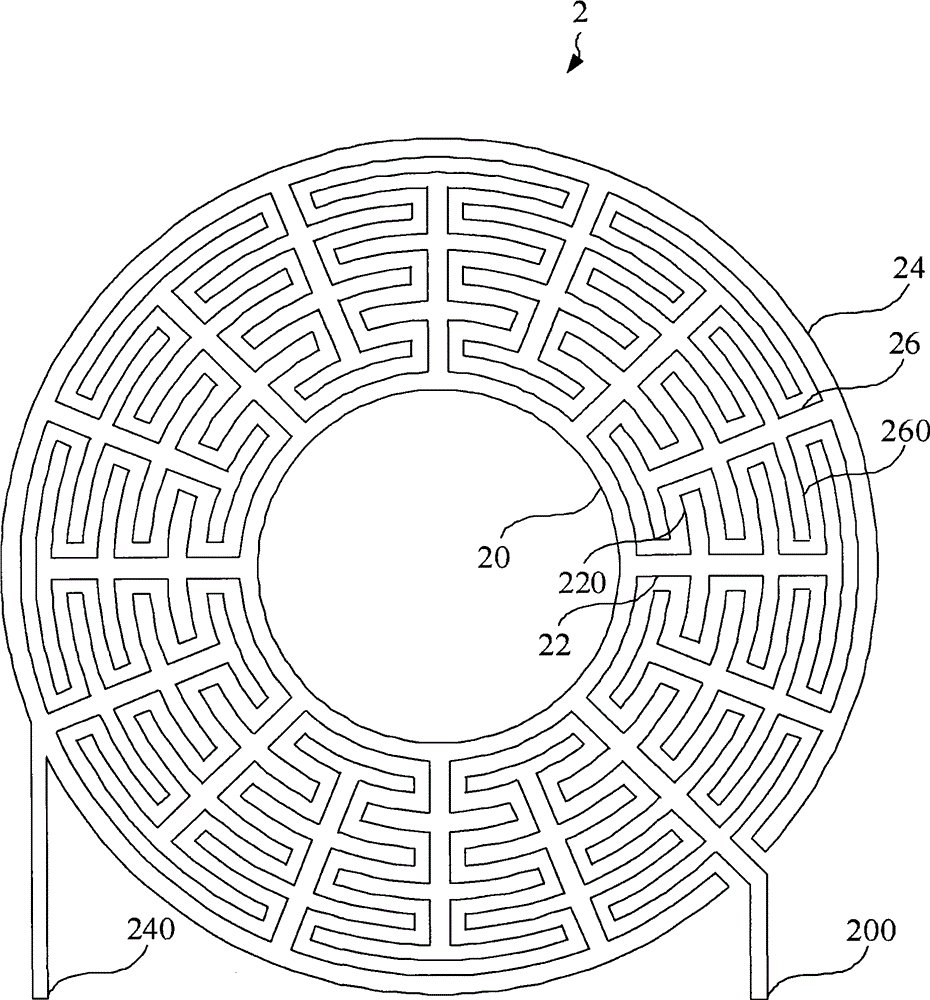

[0030] see figure 2 , figure 2 Shown is a schematic diagram of an electrode structure according to a preferred embodiment of the present invention. Such as figure 2 As shown, the present invention discloses an electrode structure 2, which is applied to a liquid lens. The electrode structure 2 includes: a first annular body 20, a plurality of first connecting parts 22, a second annular body 24 and a plurality of The second connection part 26 . A plurality of first connecting parts 22 are connected to the first annular body 20, and extend radially outward from the geometric center of the first annular body 20; a plurality of second connecting parts 26 are connected to the second annular body 24, and The geometric center of the second annular body 24 extends radially inward; meanwhile, the first annular body 20 and the second annular body 24 are on the same plane, and the geometric center of the first annular body 20 is in the same plane as the second annular body. The geo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com