In-situ nano-indentation tester based on adjustable stretching-bending preload

A nano-indentation and preload technology, which is applied in the direction of applying stable bending force to test material strength, using stable tension/pressure to test material strength, and testing material hardness, etc., to achieve good neutrality, easy to observe and image. The effect of recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

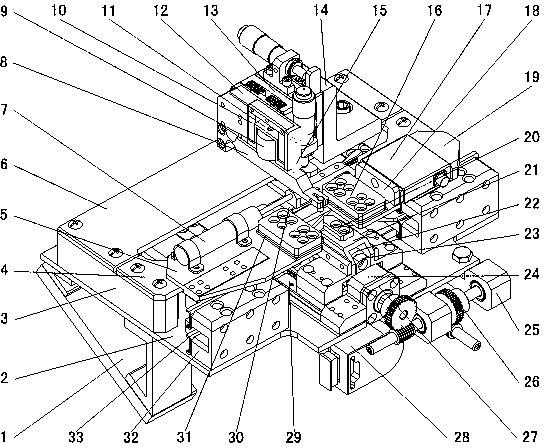

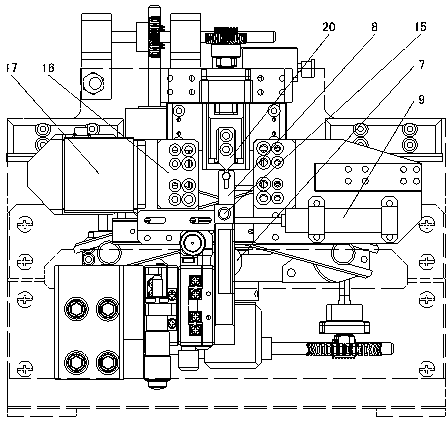

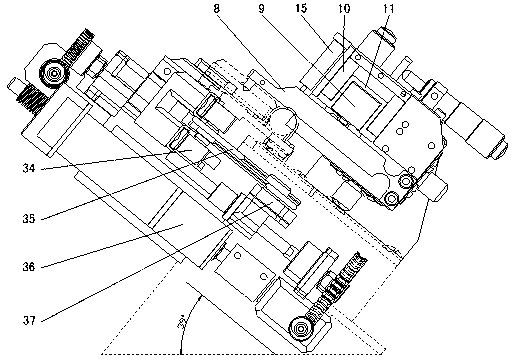

[0040] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0041] see Figure 1 to Figure 9 As shown, the in-situ nano-indentation tester based on the adjustable tensile-bending preload of the present invention includes an in-situ nano-indentation test module, a tensile preload loading module and a bending preload loading module. The indentation test module is composed of a precision displacement / force loading unit and a load / displacement signal detection unit; the tensile preload loading module is composed of a precision drive unit, a precision transmission unit, a load / displacement signal detection and control unit, and a clamping unit; The preload loading module is composed of a precision drive unit, a precision transmission unit, a load / displacement signal detection and control unit. Each subunit forms each module, and finally the whole machine is composed of three mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com