Double-layer water-cooled expansion joint

A technology of double-layer water cooling and expansion joints, applied in the field of expansion joints, can solve the problems of reducing the pressure bearing capacity of expansion joints, high maintenance costs, poor cooling effect, etc., and achieve the effects of faster flow speed, low manufacturing cost and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

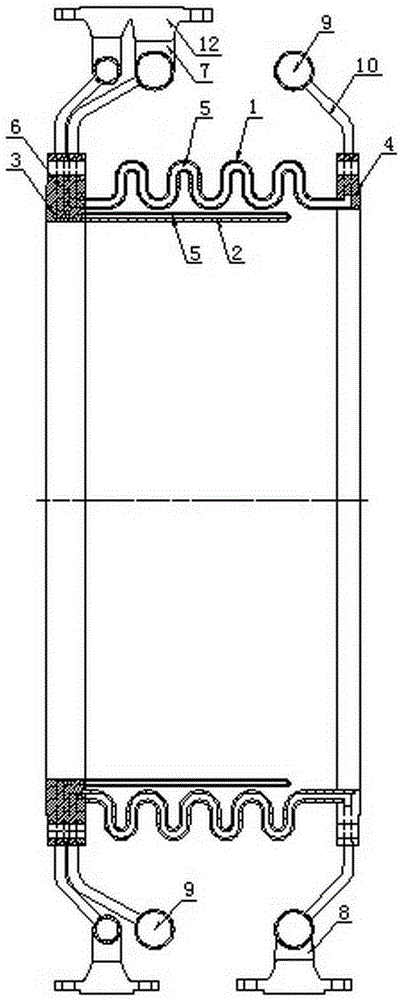

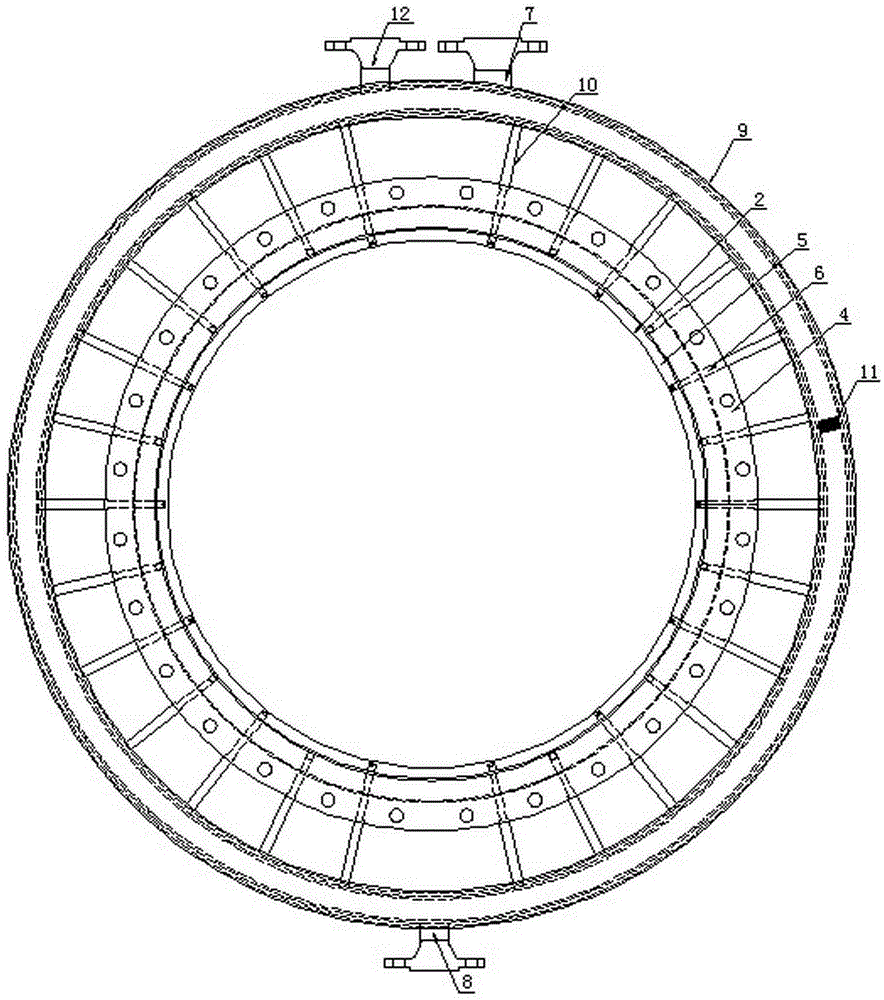

[0033] A double-layer water-cooled expansion joint, including a bellows 1, a guide tube 2, a first flange 3 and a second flange 4, and the two ends of the bellows 1 are respectively fixed to the first flange 3 and the second flange 4 connection, the guide tube 2 is fixedly sleeved in the bellows 1, and also includes a first water inlet and outlet device and a second water inlet and outlet device, and the walls of the bellows 1 and the guide tube 2 are provided with cavities 5 , the first flange 3 is provided with two inner cavities 6, the second flange 4 is provided with an inner cavity 6, and one of the inner cavities 6 of the first flange 3 passes through the cavity 5 of the bellows 1 and The inner cavity 6 of the second flange 4 communicates, and the other inner cavity 6 of the first flange 3 communicates with the cavity 5 of the guide tube 2. The first water inlet and outlet device, the first flange 3, the bellows 1 The first cooling system is formed after being connected ...

Embodiment 2

[0042] This embodiment is the same as the above embodiment, the main difference is that the second water inlet and outlet device includes a water diversion ring pipe 9, a water inlet 8, a water outlet 7 and a connecting pipe 10, and the water inlet 8 and the water outlet 7 are symmetrical It is arranged on the water diversion ring pipe 9 , and the water diversion ring pipe 9 is sleeved on the corrugated pipe 1 and communicates with the inner cavity 6 of the first flange 3 through the connecting pipe 10 . But the quantity of water diversion ring pipe 9 in the second water inlet and outlet device also can be set to two, during installation, the setting direction of water inlet 8 and water outlet 7 in the second water inlet and outlet device is preferably the same as that of the first water inlet and outlet device. The setting directions of the water port 8 and the water outlet 7 are the same.

Embodiment 3

[0044] This embodiment is the same as the above embodiment, the main difference is that: the number of connecting pipes 10 between each water diversion ring pipe 9 and the flange is 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com