Low friction plate gate valve

A flat gate valve, low-friction technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of short service life of valves, wear of valve seats and gate plates, large valve switching torque, etc., to improve service life and reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

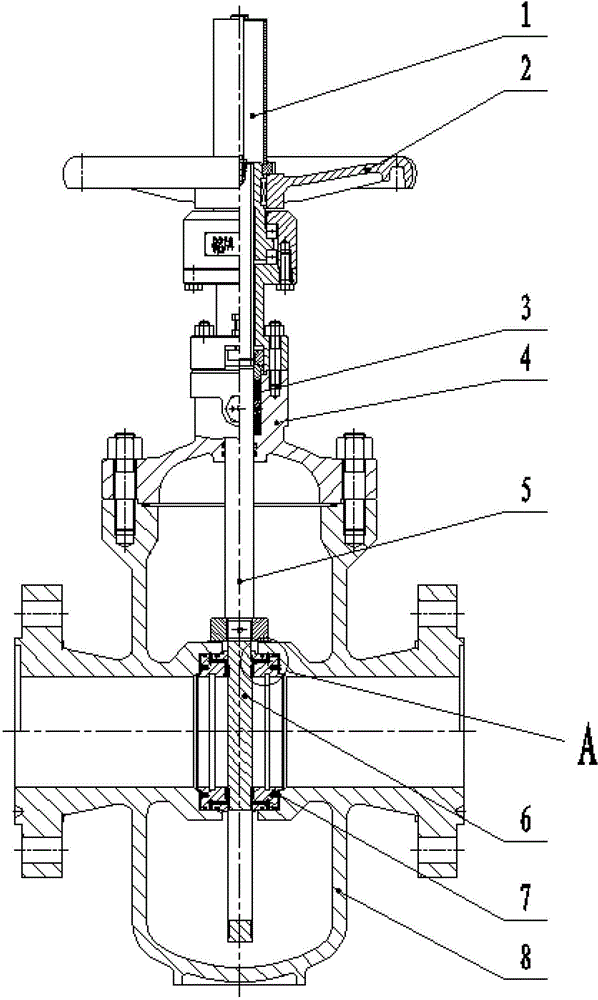

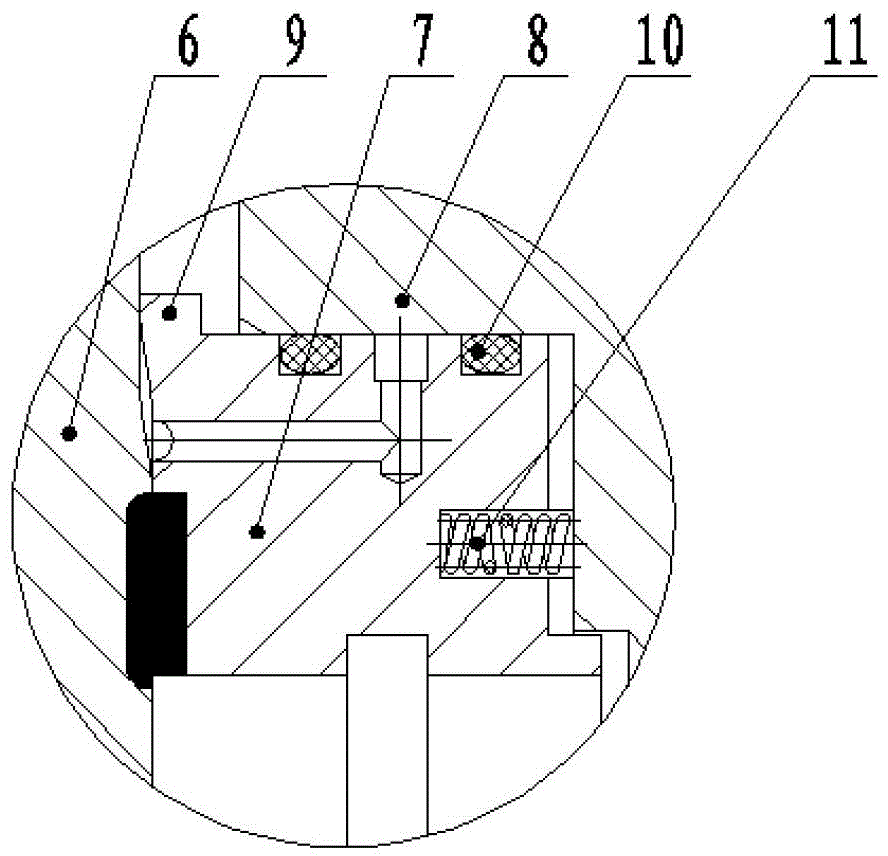

[0015] A low-friction flat gate valve, comprising a valve body 8, a valve cover 4, a valve seat 7, a gate plate 6, a valve stem 5, a hand wheel 2 and a protective cover 1, as attached figure 1 As shown, the valve cover is coaxially installed on the longitudinal upper end of the valve body, the flow channel is coaxially formed in the horizontal direction of the valve body, and a pair of valve seats are coaxially sealed and fixed in the middle of the flow channel in the valve body. There is a gate used to control the opening and closing of the flow channel; the upper end of the gate is coaxially fixed with a valve stem, the upper part of the valve stem protrudes from the valve cover and a handwheel is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com