Exhaust gas recirculation system for automobile engine

A recirculation system, automotive engine technology, applied in exhaust gas recirculation, engine components, combustion engines, etc., can solve problems such as the EGR system that has not been solved, and achieve the effect of reducing energy consumption, accurate control, and reducing ventilation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

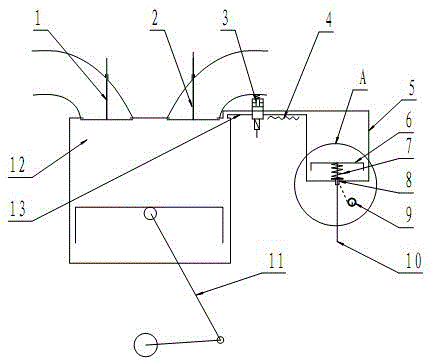

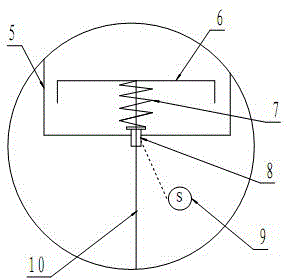

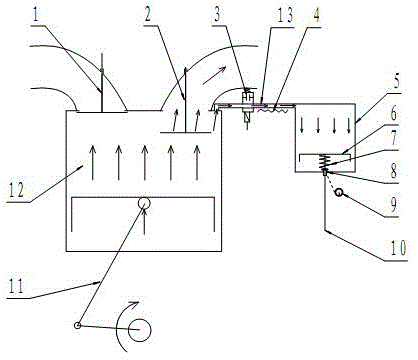

[0020] See Figure 1, figure 2 , the present invention comprises an engine cylinder 12, an auxiliary cylinder 5, an auxiliary cylinder piston 6 and an electromagnetic control valve 3, the auxiliary cylinder piston 6 is placed inside the auxiliary cylinder 5, and the auxiliary cylinder 5 and the engine cylinder 12 are provided with interconnected Passage 13, an electromagnetic control valve 3 is set on the passage 13, and the electromagnetic control valve 3 is a two-position two-way valve, which is controlled by the engine ECU; a compression spring 7 is set between the auxiliary cylinder piston 6 and the bottom surface of the auxiliary cylinder 5 A sliding guide rod 10 is installed at the center position of the bottom surface of the auxiliary cylinder piston 6, the sliding guide rod 10 is fitted with a screw sleeve assembly 8 installed on the bottom surface of the auxiliary cylinder, and the screw sleeve assembly 8 is driven by a servo motor 9, The upper end of the screw sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com