Preparation method of tri(pentafluorophenyl) borane

A kind of technology of pentafluorophenyl and pentafluorobromobenzene, applied in the field of preparation of triborane, can solve problems such as high price, application has not been paid enough attention, etc., and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

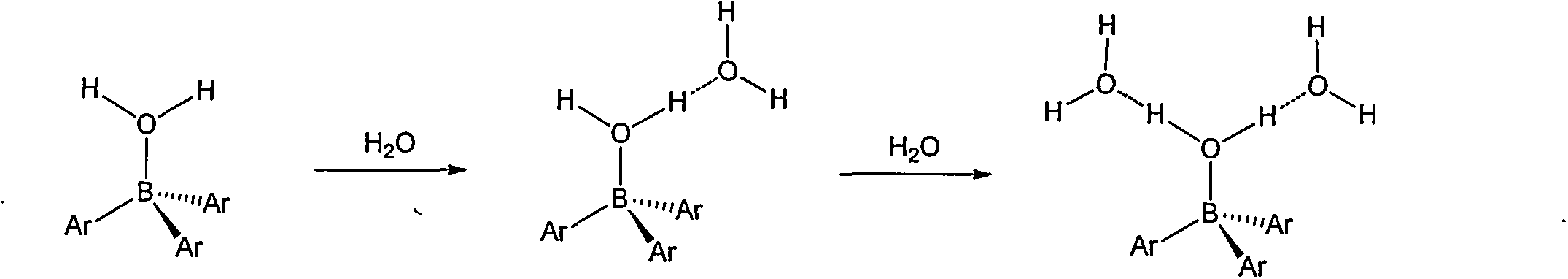

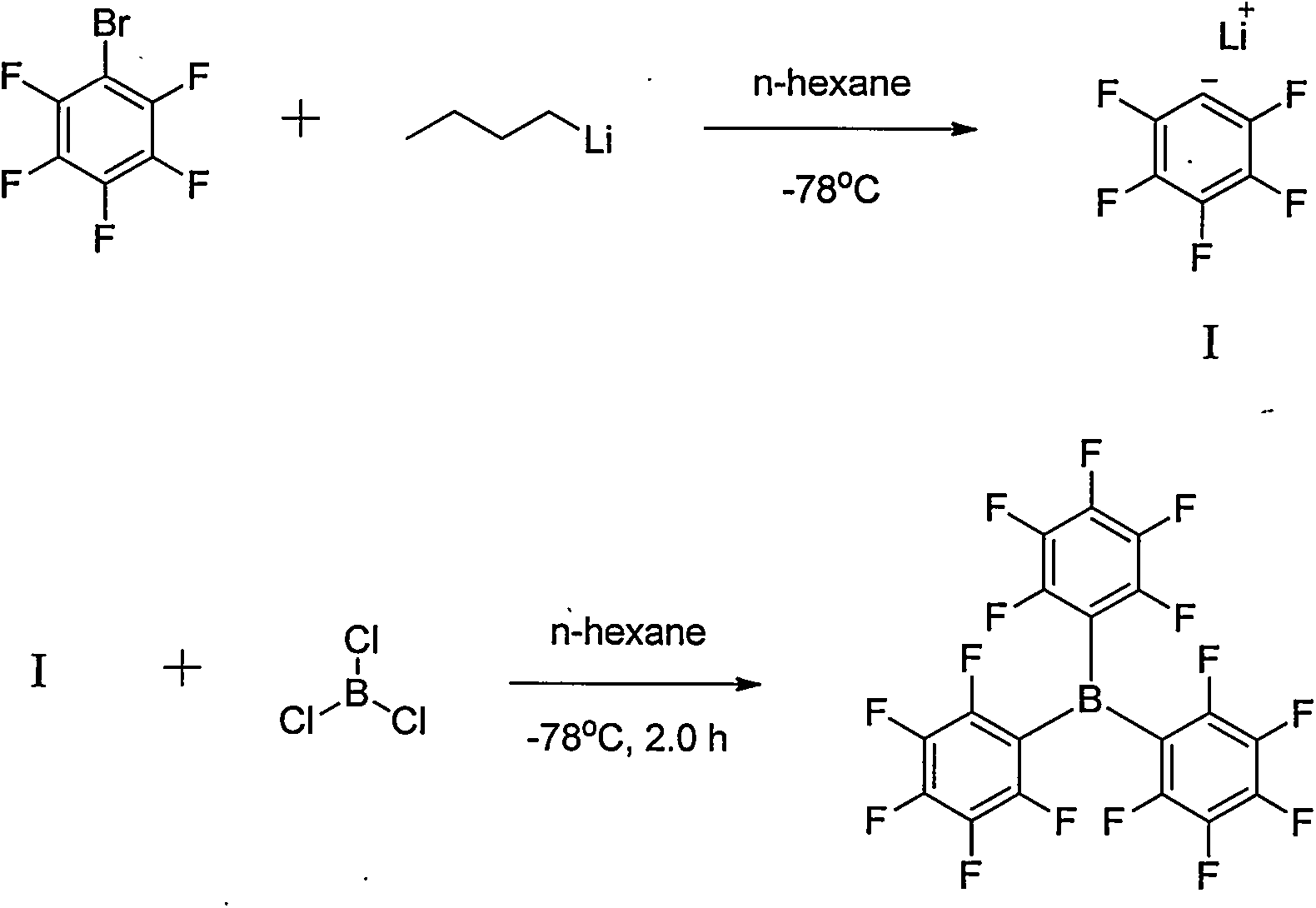

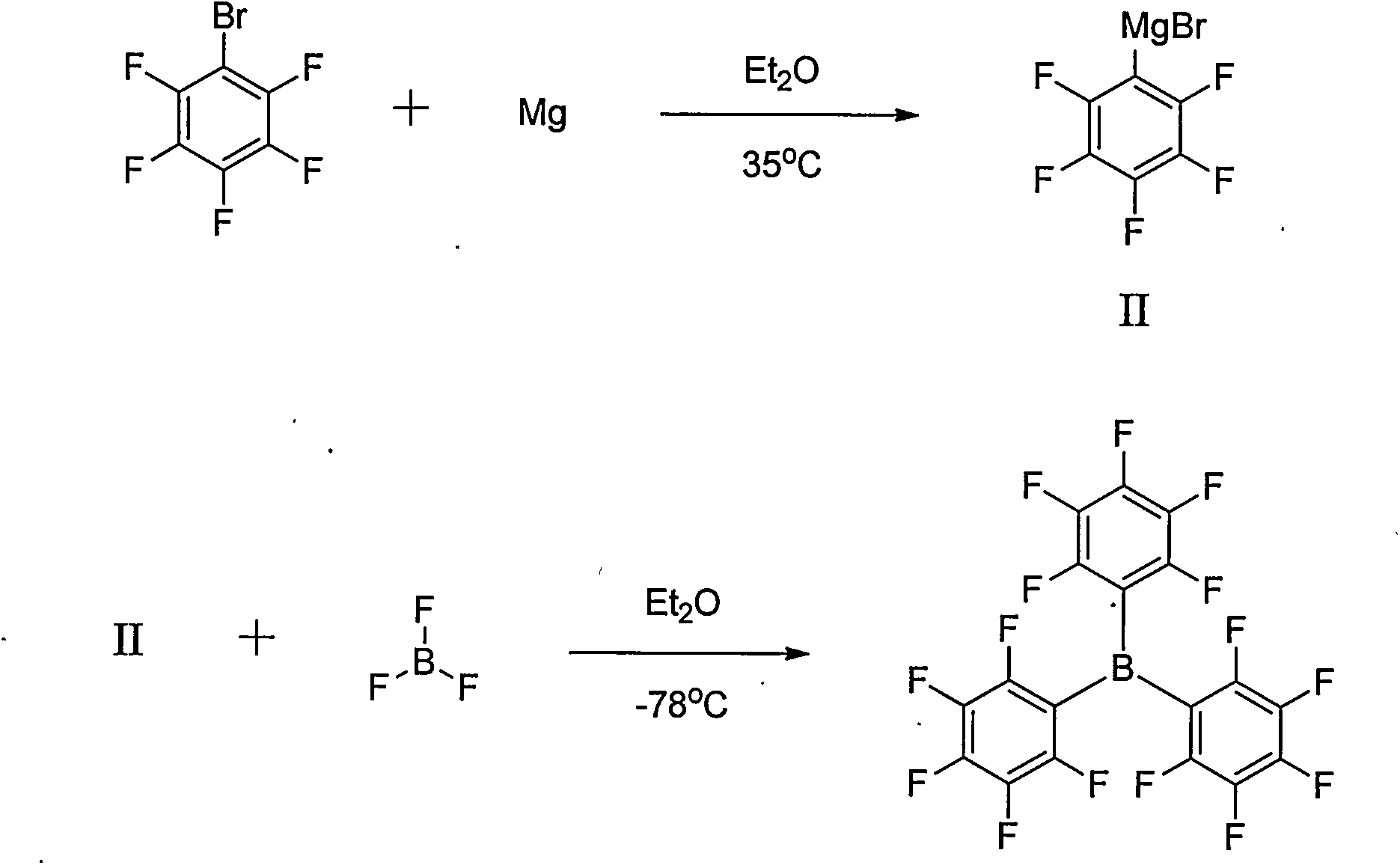

Method used

Image

Examples

Embodiment 1

[0025] After adding pentafluorobromobenzene (0.09mol, 22.2g) into a three-necked flask (250mL), 2-methyltetrahydrofuran (100mL) was added. At 25°C, n-BuLi (2.5M, 0.09mol, 36mL) was added dropwise. After reacting for 6.0h, trimethyl borate (0.03mol, 3.1g) was added dropwise at 25°C for 10min. After 16 h at 25°C, the reaction was monitored by GC. Pour the reaction solution into water, extract twice with 2-methyltetrahydrofuran, combine the organic layers, wash twice with water and once with saturated brine, dry the organic layer with sodium sulfate, evaporate 2-methyltetrahydrofuran under reduced pressure, and recover 2-Methyltetrahydrofuran was obtained as a crude product, which was recrystallized from n-hexane to obtain tris(pentafluorophenyl)borane (0.0049mol, 2.48g), with a yield of 16.2%.

Embodiment 2

[0027] After adding pentafluorobromobenzene (0.09mol, 22.2g) into a three-necked flask (250mL), 2-methyltetrahydrofuran (100mL) was added. EtMgBr (1.0M, 0.09mol, 90mL) was added dropwise at 25°C. After reacting for 6.0h, trimethyl borate (0.03mol, 3.1g) was added dropwise at 25°C for 10min. After 16 h at 25°C, the reaction was monitored by GC. Pour the reaction solution into water, extract twice with 2-methyltetrahydrofuran, combine the organic layers, wash twice with water and once with saturated brine, dry the organic layer with sodium sulfate, evaporate 2-methyltetrahydrofuran under reduced pressure, and recover 2-Methyltetrahydrofuran was obtained as a crude product, which was recrystallized from n-hexane to obtain tris(pentafluorophenyl)borane (0.0125 mol, 6.40 g), with a yield of 41.7%.

Embodiment 3

[0029] After adding pentafluorobromobenzene (0.09mol, 22.2g) into a three-necked flask (250mL), diethyl ether (100mL) was added. At 25°C, i-PrMgCl (2.0M, 0.09mol, 45mL) was added dropwise. After reacting for 6.0h, trimethyl borate (0.03mol, 3.1g) was added dropwise at 25°C for 10min. After 16 h at 25°C, the reaction was monitored by GC. Pour the reaction solution into water, extract twice with 2-methyltetrahydrofuran, combine the organic layers, wash twice with water and once with saturated brine, dry the organic layer with sodium sulfate, evaporate 2-methyltetrahydrofuran under reduced pressure, and recover 2-Methyltetrahydrofuran was obtained as a crude product, which was recrystallized from n-hexane to obtain tris(pentafluorophenyl)borane (0.0182mol, 9.28g), with a yield of 60.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com