Preparation method of antibacterial domestic ceramic

A ceramic preparation and ceramic technology, applied in the field of ceramics, can solve the problems of no antibacterial performance, insufficient antibacterial effect, and insufficient antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing antibacterial daily-use ceramics, the method comprising the following steps:

[0024] (1) The ceramic clay used for making ceramic raw materials is beaten into slurry with a beater, and the slurry is poured into the mixer for stirring and mixing evenly, and the slurry is injected into the ceramic mold, after automatic drying, the water is evenly evaporated, and the mold is demoulded after drying , to make ceramic clay adobe,

[0025] (2) Add tetrasilver tetroxide to the ceramic glaze and mix evenly to obtain a silver ion ceramic glaze containing bactericidal active ingredients. The ceramic glaze contains: silicon 59-69.4%, aluminum 7.5-12%, iron 0.08- 3.30%, titanium 0.01-1.10%, calcium 6.90-8.90%, magnesium 0.80-1.5%, potassium 1.00-2.00%, sodium 1.05-2.80%, the ceramic glaze after adding tetrasilver oxide contains: silicon 59-69.4% , aluminum 7.5-12%, iron 0.08-3.30%, titanium 0.01-1.10%, calcium 6.90-8.90%, magnesium 0.80-1.5%, potassium 1.00-...

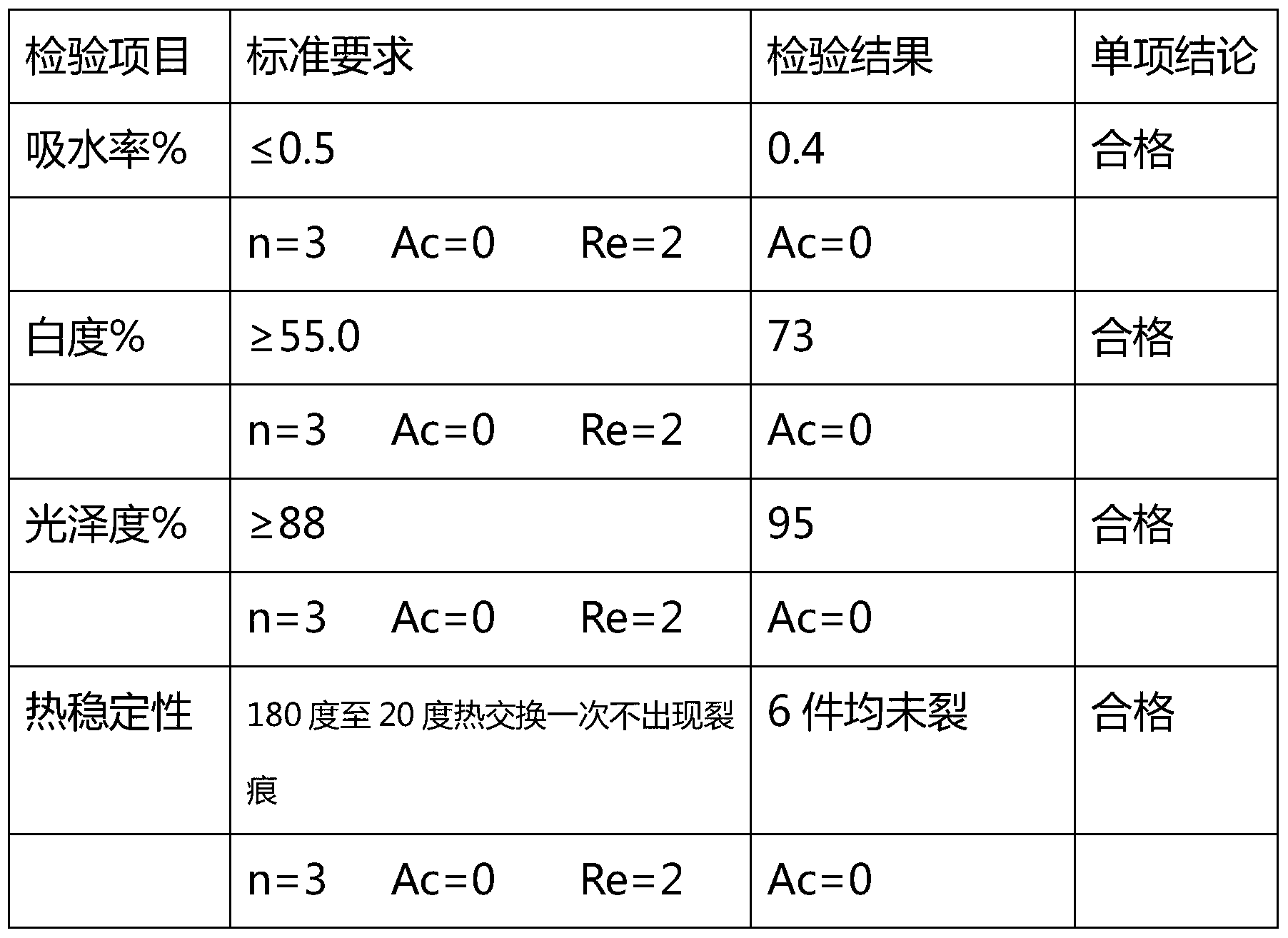

Embodiment 2

[0035] A method for preparing antibacterial daily-use ceramics, the method comprising the following steps:

[0036] (6) Use a beater to beat the ceramic clay, which is the raw material for ceramics, into a slurry. Pour the slurry into a mixer for stirring and mixing evenly, inject the slurry into the ceramic mold, and dry it automatically to evaporate the water evenly. After drying, demould , to make ceramic clay adobe,

[0037] (7) Add tetrasilver tetroxide to the ceramic glaze and mix evenly to obtain a silver ion ceramic glaze containing bactericidal active ingredients. The ceramic glaze contains: 68% silicon, 11% aluminum, 2% iron, and 1% titanium , Calcium 7%, Magnesium 1%, Potassium 1%, Sodium 2%, the ceramic glaze after adding tetrasilver oxide contains: Silicon 68%, Aluminum 11%, Iron 2%, Titanium 1%, Calcium 7%, Magnesium 1%, potassium 1%, sodium 2%, silver tetroxide 0.8%.

[0038] (8) Wipe the ceramic glaze containing silver ions on the ceramic clay adobe, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com