Printing and dyeing wastewater heat energy recovery and anti-dirty treatment method

A technology for heat recovery and antifouling treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems, to achieve the effect of high recycling efficiency, increased production, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

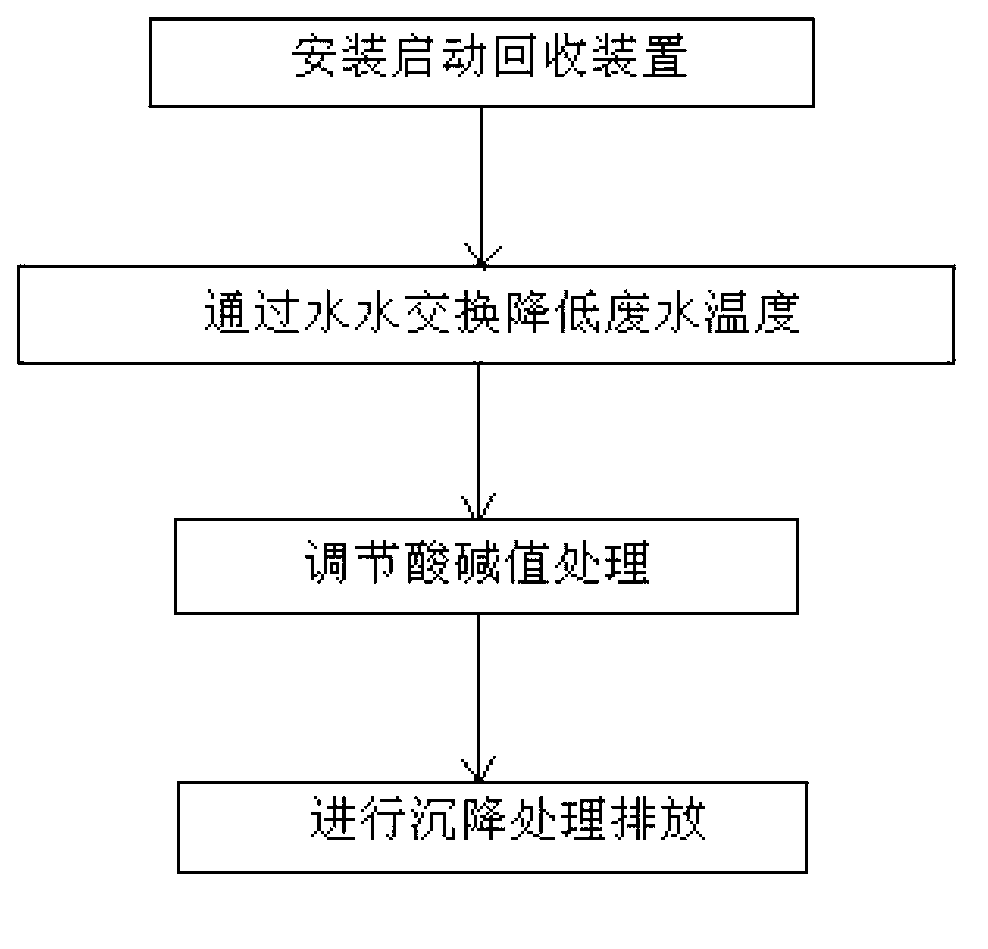

[0014] In this embodiment, the thermal energy recovery and anti-pollution treatment of printing and dyeing wastewater are realized in the thermal energy recovery and anti-pollution treatment device of printing and dyeing wastewater. The specific process includes installing and starting the recovery device, reducing the temperature of the wastewater through water-water exchange, adjusting the pH value treatment, and performing sedimentation Four steps to deal with emissions:

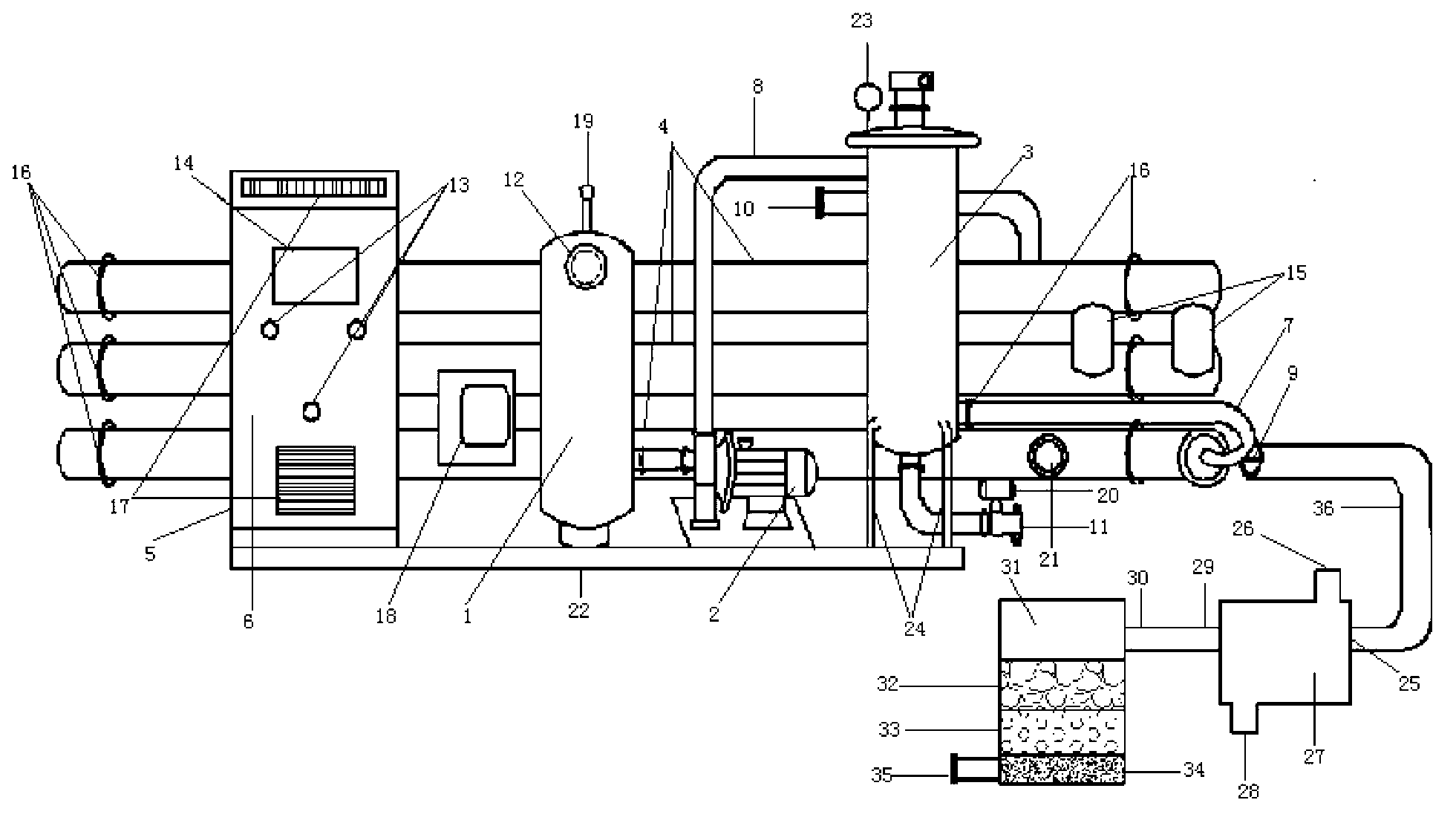

[0015] (1) Install and start the recovery device: first fix and install the components in the recovery device according to the conventional connection structure, place the centrifugal pump 2 in the high-temperature waste water pool in the production workshop, and then connect the clean water inlet 10 to the tap, The outlet 35 is placed at the entrance of the next wastewater treatment process, and finally the control switch in the switch box 18 is activated to allow the recovery device to start working;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com