System and method for automatically changing multi-vehicle type car body positioning fixtures for flexible welding of robot

A car body positioning and automatic replacement technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high setting, high manufacturing cost, high investment cost, etc., and achieve simple structure, flexible operation and convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

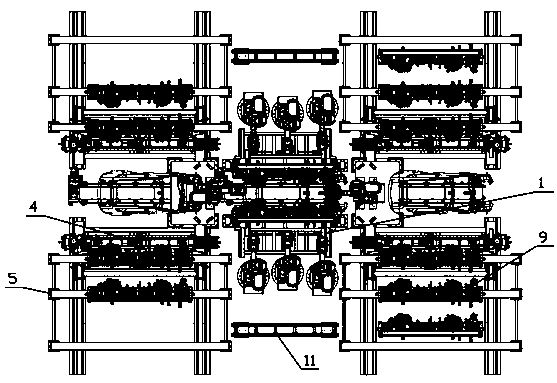

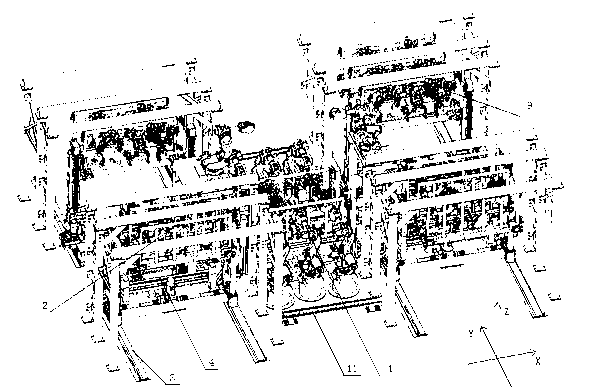

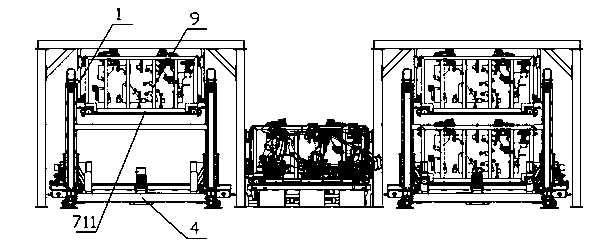

Embodiment 1

[0060] The body positioning fixture automatic replacement system for multi-model robot flexible welding includes a central positioning mechanism 1 and a body fixture storage mechanism. The body fixture storage mechanism includes two sets of mobile storage mechanisms 2 symmetrically arranged on both sides of the central positioning mechanism 1. Each set The mobile storage mechanism 2 includes a Y-direction track 3, a mobile lifting mechanism 4 and a vehicle body positioning fixture storage warehouse 5 arranged above the Y-direction track 3. The mobile lifting mechanism 3 includes an X-direction traveling mechanism 6, a Y-direction traveling mechanism 7 and a Z To the lifting mechanism 8, the Y-direction traveling mechanism 7 is set on the Y-direction track 2, and the Y-direction traveling mechanism 7 moves in the Y-direction on the Y-direction track 2; Track 71 and Z-direction lifting track 72, the X-direction traveling mechanism 6 is sleeved on the X-direction travel rail 71, a...

Embodiment 2

[0084] The body positioning fixture automatic replacement system for multi-model robot flexible welding includes a central positioning mechanism 1 and a body fixture storage mechanism. The body fixture storage mechanism includes two sets of mobile storage mechanisms 2 symmetrically arranged on both sides of the central positioning mechanism 1. Each set The mobile storage mechanism 2 includes a Y-direction track 3, a mobile lifting mechanism 4 and a vehicle body positioning fixture storage warehouse 5 arranged above the Y-direction track 3. The mobile lifting mechanism 3 includes an X-direction traveling mechanism 6, a Y-direction traveling mechanism 7 and a Z To the lifting mechanism 8, the Y-direction traveling mechanism 7 is set on the Y-direction track 2, and the Y-direction traveling mechanism 7 moves in the Y-direction on the Y-direction track 2; Track 71 and Z-direction lifting track 72, the X-direction traveling mechanism 6 is sleeved on the X-direction travel rail 71, a...

Embodiment 3

[0111] The body positioning fixture automatic replacement system for multi-model robot flexible welding includes a central positioning mechanism 1 and a body fixture storage mechanism. The body fixture storage mechanism includes two sets of mobile storage mechanisms 2 symmetrically arranged on both sides of the central positioning mechanism 1. Each set The mobile storage mechanism 2 includes a Y-direction track 3, a mobile lifting mechanism 4 and a vehicle body positioning fixture storage warehouse 5 arranged above the Y-direction track 3. The mobile lifting mechanism 3 includes an X-direction traveling mechanism 6, a Y-direction traveling mechanism 7 and a Z To the lifting mechanism 8, the Y-direction traveling mechanism 7 is set on the Y-direction track 2, and the Y-direction traveling mechanism 7 moves in the Y-direction on the Y-direction track 2; Track 71 and Z-direction lifting track 72, the X-direction traveling mechanism 6 is sleeved on the X-direction travel rail 71, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com