Plastic backrest chair

A technology of back chairs and plastics, applied in the field of furniture, can solve the problems of monotonous colors, shrinkage cavities, inflexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

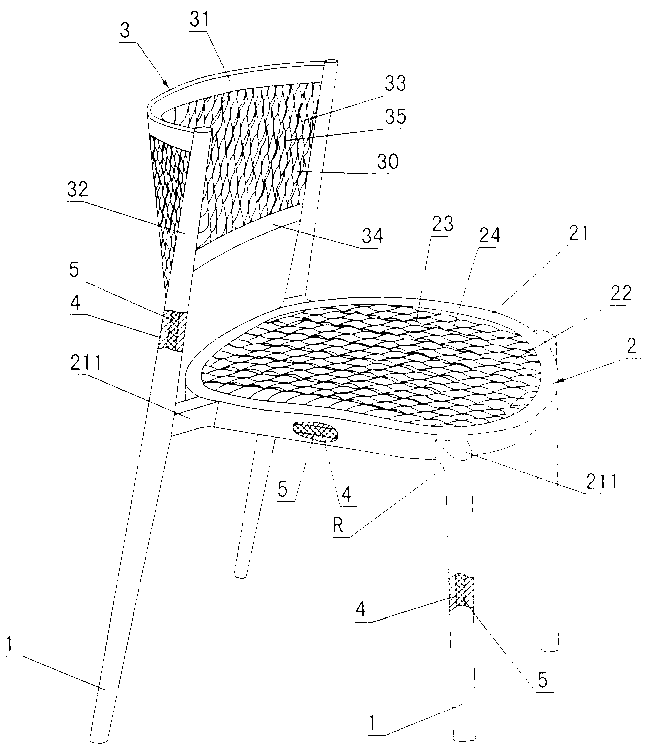

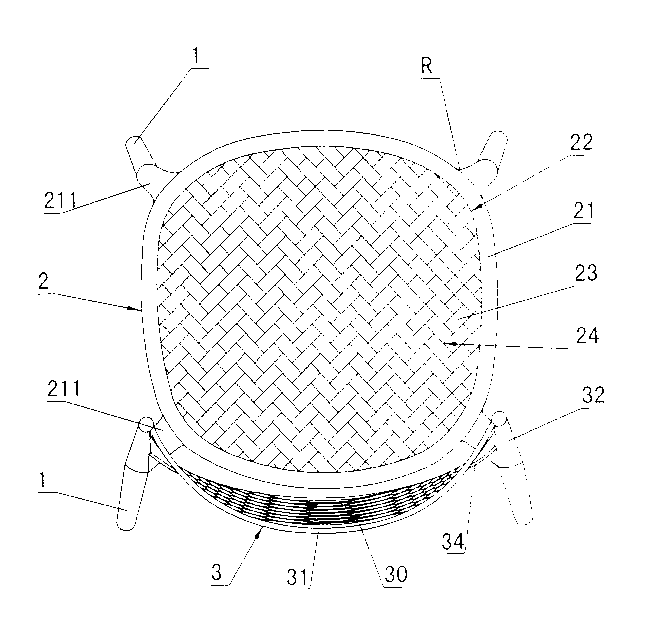

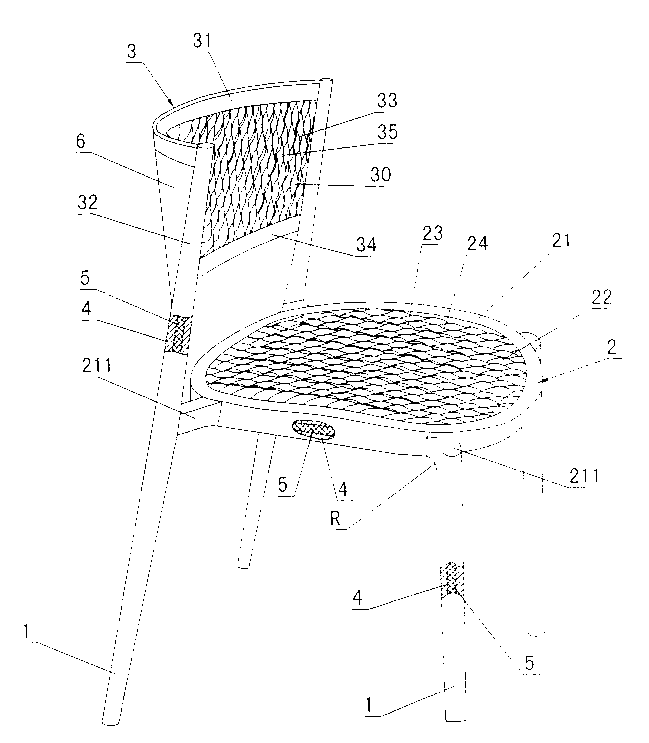

[0010] The present invention relates to a plastic back chair, such as figure 1 — image 3 As shown, it includes a seat 2, a chair foot 1 and a chair back 3, and it is characterized in that the seat 2 includes a frame 21 and a seat plate 22, and the frame is formed with an outwardly protruding beam 211, through which Connect the chair legs 1, the chair legs are four, the two rear chair legs extend upwards to be the main rod 32 of the chair back, and the two main rods are shaped on an integrated curved upper bow bar 31 and lower bow bar 34, the upper and lower bows A backboard 30 is set in the bar and two main rods 32, and the upper surfaces of the backboard 30 and the seat board 22 are respectively shaped on rattan-like ribs 33, 23 and grooves 35, 24, and the chair legs 1 , beam 211, frame 21, main rod 32 and upper and lower arches 31, 34 are respectively made up of outer layer 4 and core layer 5 in the outer layer. In terms of product design, this solution divides the chair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com