Combined full-automatic tobacco leaf selecting and selected acquiring line

A fully automatic and combined technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as high labor intensity, increased labor workload, and complicated operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

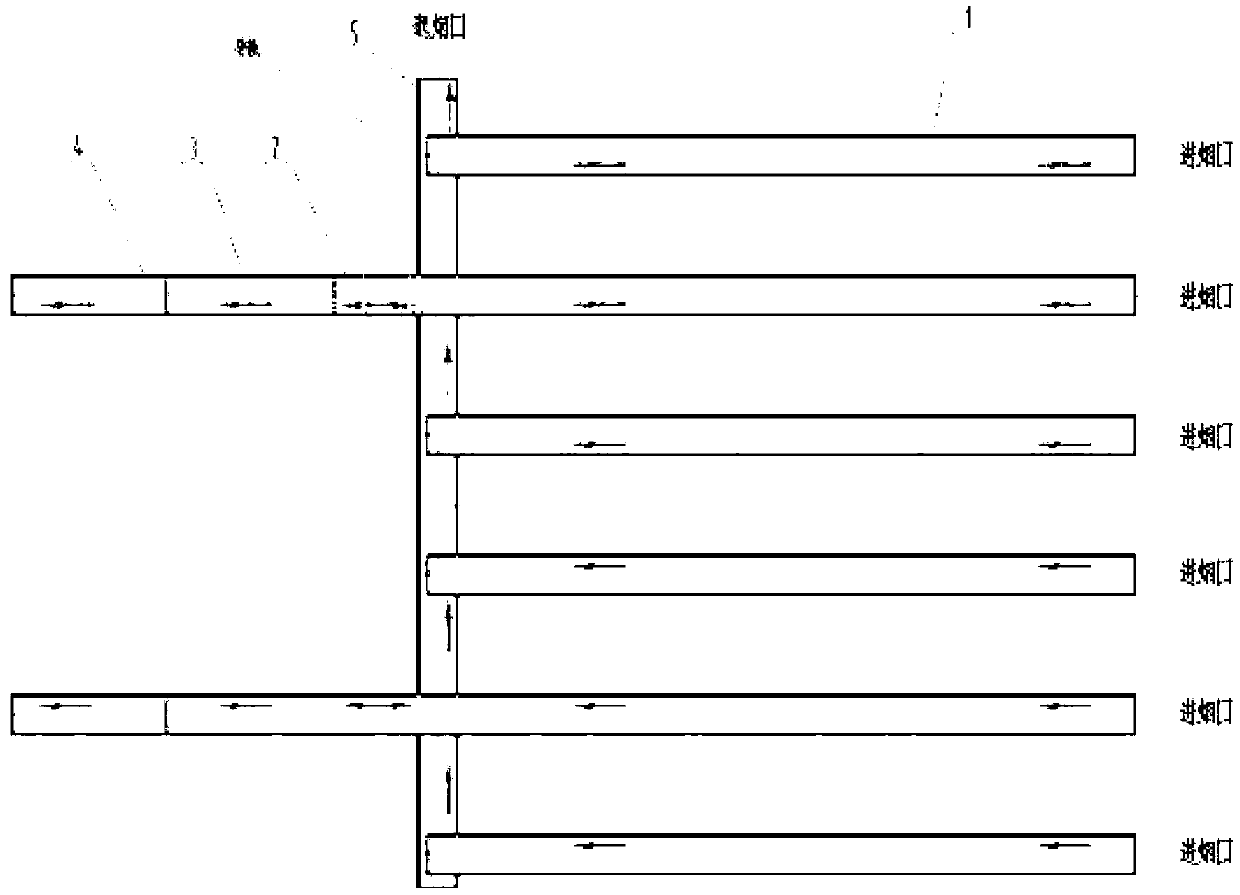

[0018] As shown in the figure, the present invention includes a smoke inlet selection conveyor ⑴, characterized in that: a grading conveyor ⑵ is arranged at the tail of the conveyor belt of the smoke inlet selection conveyor ⑴, and the two ends of the grading conveyor ⑵ are respectively arranged There is a weighing conveyor ⑶ consistent with the conveying direction of the graded conveyor ⑵ and a smoke exhaust conveyor ⑸ perpendicular to the conveying direction of the graded conveyor ⑵.

[0019] Tobacco leaves are manually placed on the tobacco inlet selection conveyor ⑴ at the smoke inlet. Tobacco leaves are manually selected during the conveying process on the tobacco inlet selection conveyor ⑴, and substandard and other non-smoke debris are selected separately Placed in the small box next to the selection conveyor ⑴, the selected tobacco leaves are conveyed to the grading conveyor ⑵ through the selection conveyor ⑴, and the grading personnel perform the grading on the gradin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com