Bound pork processing method

A processing method and technology for meat pieces, applied in the fields of application, food preparation, food science, etc., can solve the problems of low degree of mechanization application, products cannot be matured at one time, difficult to produce in large areas, save raw materials and labor costs, and is beneficial to The effect of mechanized production and improvement of work level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

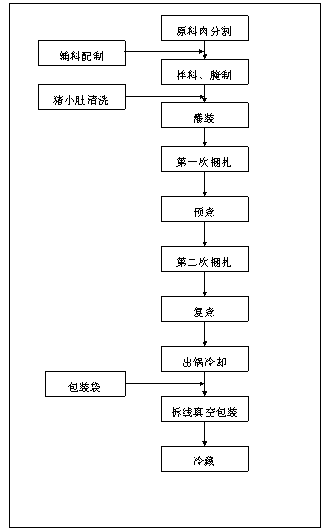

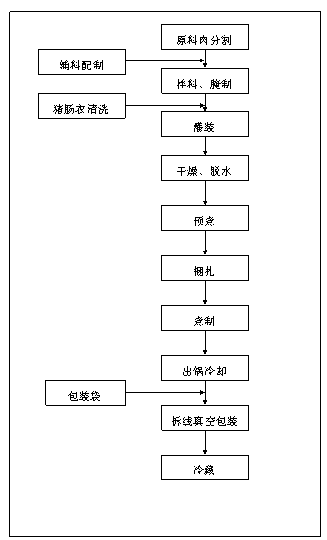

Image

Examples

Embodiment 1

[0025] Take 100 kilograms of lean pork hind leg meat, cut into small pieces weighing 60-70 grams / piece, add 12 kilograms of auxiliary materials, the auxiliary materials include sucrose, salt, ginger, spices, sodium glutamate, koji, Red yeast red, etc.; for mixing, the mixing time is 15 minutes, the marinating time is 22 hours, the temperature of the meat material is controlled at 0-10 ℃, and the meat material is massaged for 3 minutes every 2 hours; the meat material after marinating Vacuum filling is carried out with a filling machine, and the meat is filled into the artificial pig casing. The diameter of the artificial pig casing is 9 cm and the length is 15 cm. It is filled with 500 grams each, and the shape becomes oval after filling. The semi-finished product is filled with aluminum cards. Click the button and hang it on the drying car; the filled semi-finished product is heated in the drying oven, and the temperature of the oven is controlled to 80°C for 4.5 hours to remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com