coolant pump

A technology for coolant pumps and pump shafts, applied to pumps, pump devices, pump components, etc., can solve problems such as small structural space/installation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

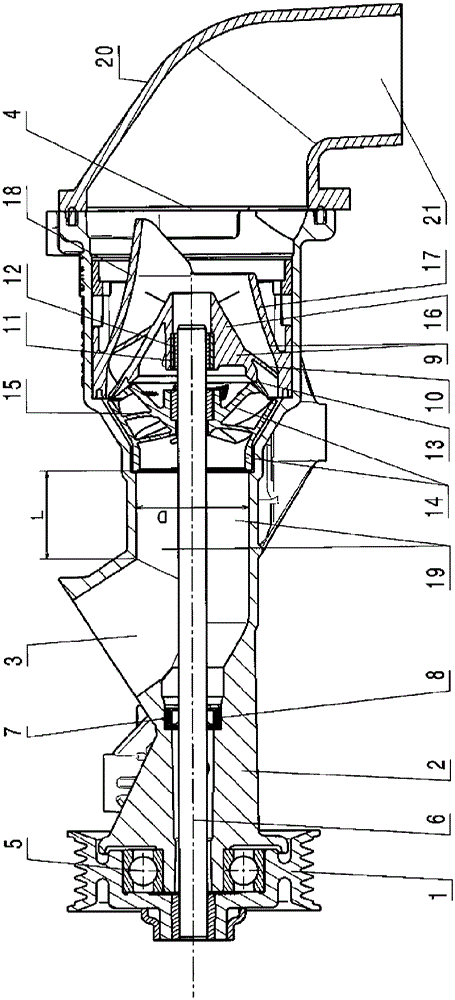

[0035] The axial flow coolant pump according to the present invention has: a pump housing 2; an inlet 3 arranged at the pump housing on the suction side and an outlet 4 arranged at the pump housing on the pressure side; The pump bearing 5 is rotatably supported in the pump housing 2 or at the pump shaft 6 connected to the pulley 1 in a rotationally fixed manner; on the drive side, beside the inflow port 3, in a seal seat 7 in the pump housing 2 A pump shaft seal 8 arranged between the seal seat 7 and the pump shaft 6; a guide wheel 9 with guide vanes 10 arranged in the pump housing 2 in a torsion-resistant manner, and a bearing receptacle is present in the guide wheel 9 11. A sliding bearing 12 is arranged therein, and the pump shaft 6 is supported in the sliding bearing 12 with its end of the pump shaft opposite to the driving side (for example, the pulley 1), wherein, on the pump shaft 6, at the inlet In the direction of 3, a running wheel 14 with blades 15 is arranged in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com