Alkaline fuel cell cathode carbon catalyst and preparation method thereof

A fuel cell cathode and carbon-based catalyst technology, which is applied in the direction of battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that the catalytic activity is lower than that of noble metals and their alloy catalysts, and the preparation process cannot meet large-scale production. Problems such as poor tolerance and long-term running stability, etc., achieve the effect of low price, easy purchase and preparation, and good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Preparation of CFePc carbon-based non-noble metal catalyst with core-shell nanostructure

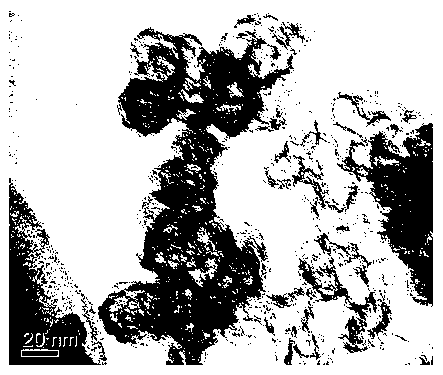

[0035] Iron phthalocyanine FePc (purchased from Alfa Aesar) with a specific surface area of 1400 m 2 / g of high specific surface conductive carbon black EC600JD (purchased from Cabot Company in the United States) weighed the two raw materials with a mass ratio of 1:1, mixed them briefly, put them into a mechanical ball mill and milled them for 0.5 hours, and took out the milled product as the nucleus Shell nanostructured CFePc carbon-based non-noble metal catalysts (such as figure 1 shown).

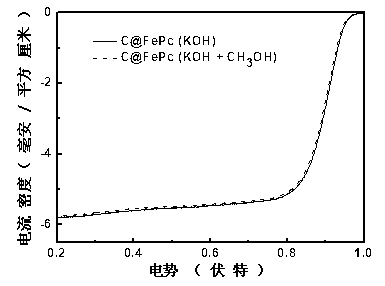

[0036] 2) Test the oxygen reduction performance of CFePc carbon-based non-noble metal catalysts

[0037] Weigh an appropriate amount of carbon-based non-precious metal catalyst powder and evenly disperse it in the isopropanol solution containing Nafion. The catalyst dispersion is coated on the surface of the glassy carbon electrode according to the catalyst loading of 20 μg on the ...

Embodiment 2

[0046] 1) With a specific surface area of 250 m 2 The preparation of the catalyst when the conductive carbon black is the inner core

[0047] Iron phthalocyanine FePc (purchased from Alfa Aesar) with a specific surface area of 250 m 2 / g of high specific surface conductive carbon black Vulcan XC72 (purchased from Cabot Company in the United States) weighed two raw materials with a mass ratio of 1:1, put them into a mechanical ball mill for 0.5 hours after simple mixing, and took out the ball-milled product. Core-shell nanostructured CFePc carbon-based non-noble metal catalysts.

[0048] 2) Test the catalytic performance of the catalyst

[0049] Weigh an appropriate amount of carbon-based non-precious metal catalyst powder and evenly disperse it in the isopropanol solution containing Nafion. The catalyst dispersion is coated on the surface of the glassy carbon electrode according to the catalyst loading of 20 μg on the electrode surface to prepare a working electrode. At...

Embodiment 3

[0054] 1) Preparation of the catalyst when the mass ratio of FePc to C is 1:4

[0055] Iron phthalocyanine FePc (purchased from Alfa Aesar) with a specific surface area of 1400 m 2 / g of high specific surface conductive carbon black EC600JD (purchased from Cabot Company in the United States) weighed the two raw materials with a mass ratio of 1:4, put them into a mechanical ball mill for 0.5 hours after simple mixing, and took out the ball-milled product as the nucleus Shell nanostructured CFePc carbon-based non-noble metal catalysts.

[0056] 2) Test the catalytic performance of the catalyst

[0057] Weigh an appropriate amount of carbon-based non-precious metal catalyst powder and evenly disperse it in the isopropanol solution containing Nafion. The catalyst dispersion is coated on the surface of the glassy carbon electrode according to the catalyst loading of 20 μg on the electrode surface to prepare a working electrode. At the same time, a commercially available 20 wt% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com